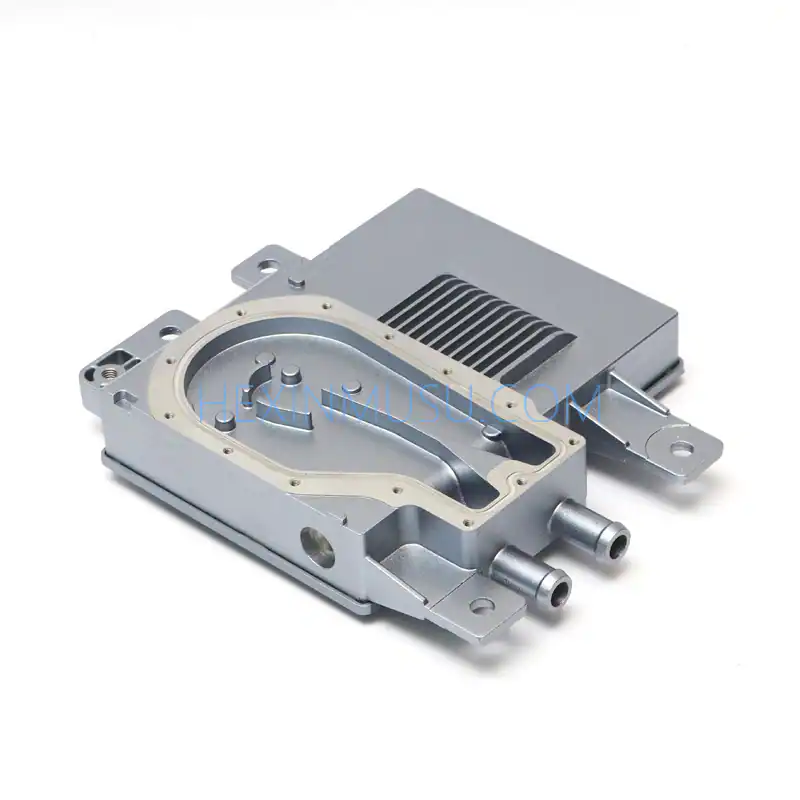

As the core power conversion component of the turbocharging system, the working principle of the scroll disk is based on the precision-designed involute scroll surface, which drives the disk to rotate at high speed through the kinetic energy of the exhaust gas flow, and efficiently converts thermal energy into mechanical energy. Hersin relies on its own innovative Low-pressure casting (math.) genus Gravitational casting The process, combined with directional solidification control technology, ensures the geometric accuracy of the scroll tooth profile and the micro-density of the material, and maintains stable airtightness and dynamic balance under high temperature and high pressure environment, which significantly improves the efficiency of the turbine operation and the reliability of the system. Ningbo Hersin scroll disk adopts low-pressure gravity casting process, based on A356-T6 high strength and high pressure. aluminum Targeted development, designed to meet the extreme conditions of turbocharging systems.

| Process Characteristics | Description of technical parameters/advantages |

|---|---|

| Filling Pressure | 0.2-0.6MPa (closed-loop pressure control system) |

| Mold temperature gradient | 200-350℃ zoned temperature control (±5℃ accuracy) |

| solidification time | 90-150s (adaptive adjustment according to component wall thickness) |

| Porosity Control | ≤0.5% (X-ray flaw detection class A standard) |

| surface roughness | Ra≤6.3μm (cast surface, no secondary fine polishing) |

| Dimensional tolerances | Class CT7 (ISO 8062 standard) |

Quality Assurance System:

authenticate and endorse: GM GMW3059 Aluminum Alloy Casting Specification

process control: Real-time monitoring of casting process, mold filling speed (0.8-1.2m/s) and mold temperature profile.

Testing Standards: 100% 3D blue light scanning (accuracy ±0.03mm) + helium mass spectrometry leak detection (leak rate ≤0.25mL/min)

application scenario

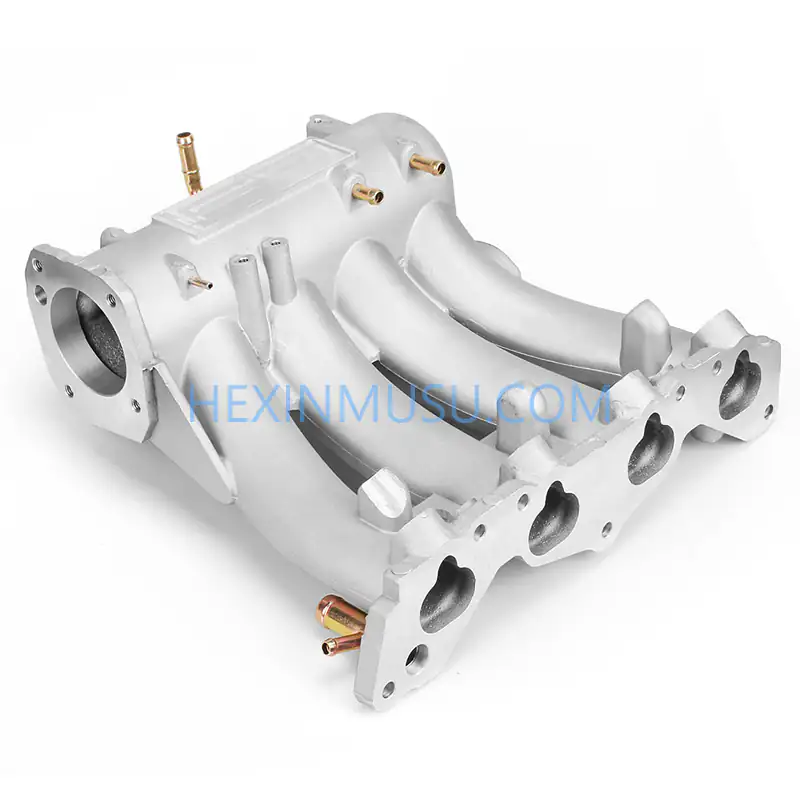

1. Turbocharging system optimization

Dynamic components designed specifically for gasoline/diesel turbochargers to enhance exhaust gas drive efficiency by 12-15% through precision scroll surfaces, helping to achieve National VI emission standard requirements. Suitable for BorgWarner, Honeywell and other mainstream supercharger platforms.

2. Thermal management of new energy vehicles

Applied to PHEV/HEV electric supercharger system, the lightweight design (58% weight reduction compared with traditional steel parts) significantly improves the energy density, and with heat-resistant coating effectively solves the problem of thermal degradation of the motor system.

3. Commercial vehicle durability upgrades

The enhanced version developed for long-distance working conditions of heavy trucks has been verified by Cummins ISX series bench through the directional grain control technology, which enables the parts to maintain >100,000km warranty cycle even under the continuous high backpressure environment.