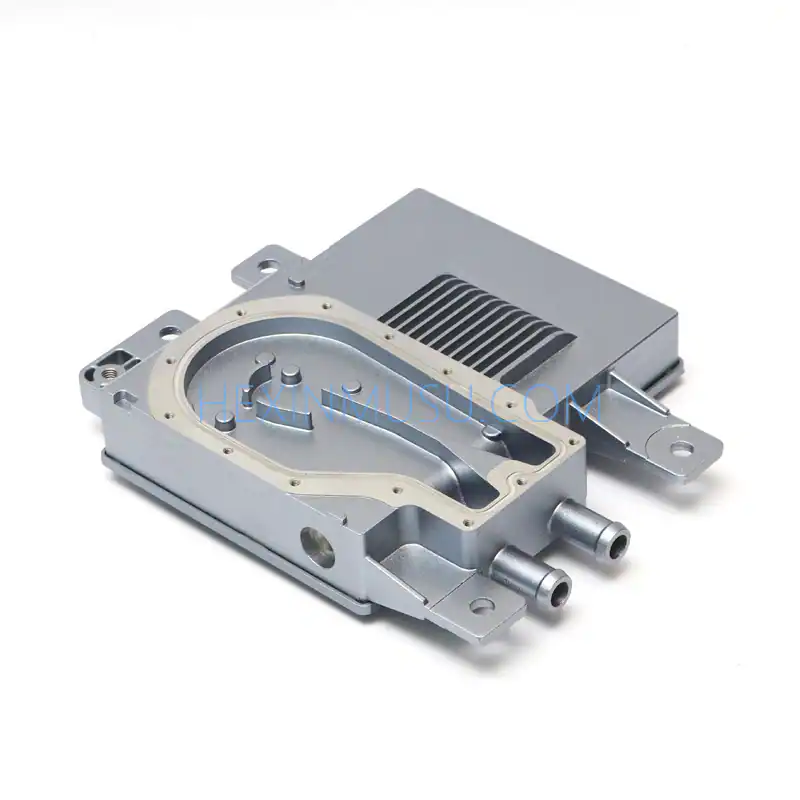

As the core fixed component of the turbocharging system, the scroll static disk works in conjunction with the scroll dynamic disk to form a closed compression chamber based on high-precision involute swirl surfaces, which guides the orderly expansion of the exhaust gas flow through static geometric constraints to maximize the efficiency of kinetic energy transfer. Hersin adoptsLow-pressure castingtogether withGravitational castingComposite process, combined with gradient cooling and directional solidification technology, to ensure that the static disk tooth shape surface geometric accuracy and matrix densification, maintain excellent dimensional stability and creep resistance under high temperature alternating stress, provide reliable sealing boundary for high-speed operation of the dynamic disk.

| parameter term | Technical indicators |

|---|---|

| Filling Pressure | 0.15-0.5MPa (Intelligent differential pressure compensation system, suitable for filling complex curved surfaces) |

| Mold temperature gradient | 180-320℃ multi-zone temperature control (dynamic heat flow balance, accuracy ±3℃) |

| solidification time | 100-180s (based on intelligent regulation of topology-optimized structures) |

| Porosity Control | ≤0.4% (X-ray flaw detection level B standard, zero defects in critical areas) |

| surface roughness | Ra ≤ 5.0μm (near net shape, no grinding of mating surfaces) |

| Dimensional tolerances | CT6 grade (ISO 8062 standard, tooth top clearance control ±0.02mm) |

Quality Assurance System

- authenticate and endorse: Compliance with MAHLE turbine component durability specifications

- process control:

- Dynamic optimization of casting parameters (filling speed 0.5-1.0 m/s, matching static disk surface complexity)

- Online monitoring of grain orientation (to ensure that the equivalent force on the root of the scroll tooth is ≤120 MPa)

- Testing Standards:

- 100% industrial CT scan (5 μm resolution, detection of internal microcracks)

- Helium mass spectrometry dual-channel leak detection (leakage rate ≤ 0.15mL/min, stricter than the dynamic disk sealing requirements)

application scenario

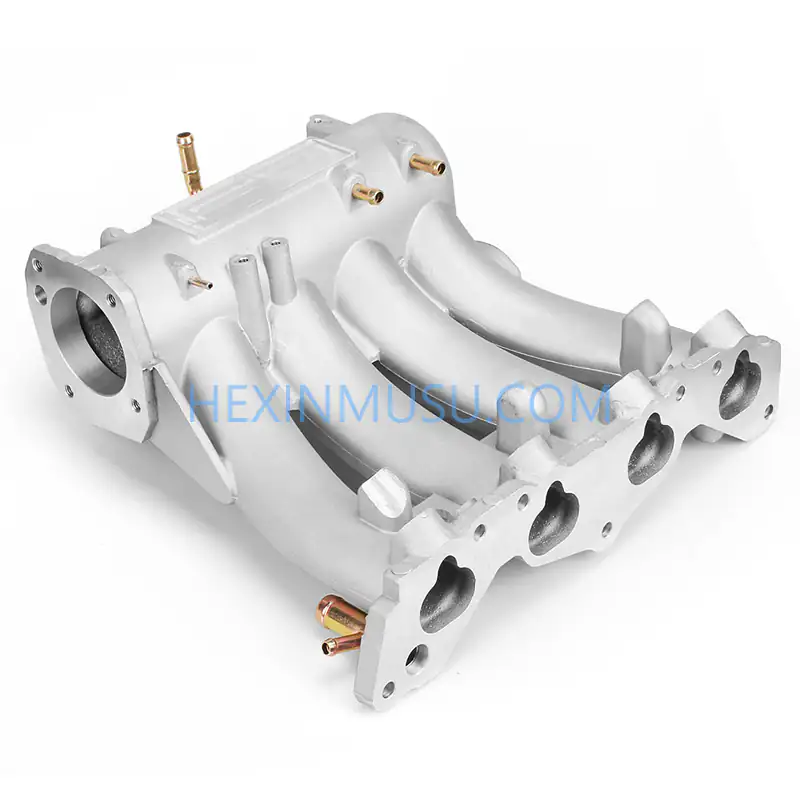

- Highly responsive turbocharging system

Matched with a twin-scroll tube supercharger design, it reduces airflow separation loss by optimizing the static disk guide surface, and improves low-speed torque 15%-20% to meet the demand for transient response in passenger cars (e.g., Volkswagen EA888 Gen3 platform). - Hydrogen Fuel Cell Air Pressure System

Adopting nickel-based alloy infiltration treatment, the wet hydrogen corrosion resistance is improved by 3 times, and it is suitable for 200kPa grade fuel cell air compressor, which helps to improve the range by 8%-12% (has passed Ballard system durability test). - Booster Module for Construction Machinery

The reinforced version of the static disk with integrated internal cooling runners has an operating temperature tolerance of 650°C. It supports high load intermittent conditions such as excavators/loaders, and has an MTBF (Mean Time Between Failure) of more than 8,000 hours.

Technical Highlights

- Bionic scroll tooth design: CFD simulation-based asymmetric tooth shape optimization to reduce airflow pulsation noise by 6-8dB

- Gradient functional materials: Surface high silicon aluminum matrix composite (SiC content 12%), the core maintains the toughness of A356-T6, and the thermal shock resistance is improved by 40%.

- Digital Twin Calibration: real-time interaction between casting process and ANSYS simulation model, key dimensions of a pass rate ≥ 99.3%