Commonly used casting aluminum alloy grades

Date: 2025-01-16 Categories: Blog Views: 6510

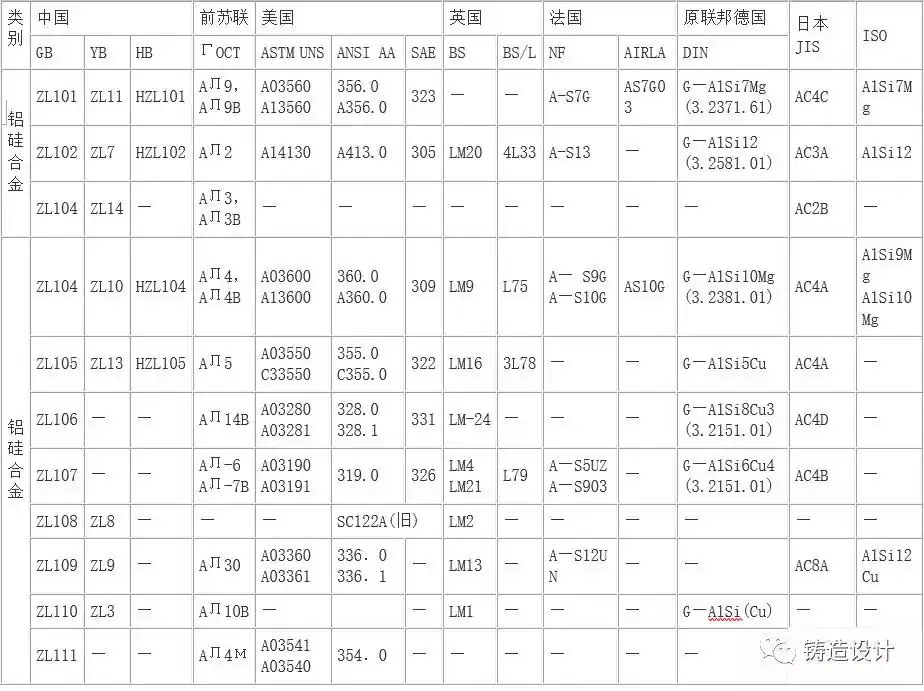

cast (pour metal into a mold) aluminum It means that by adding various metal elements inside the aluminum, by different different metal elements will have an effect on the Aluminum alloys produce different performance effects Different countries usually have different grades for the same casting aluminum alloy, Hershey's engineers have sorted out the following more common casting aluminum alloys, the comparison of grades in various countries.

Main features and applications of each brand of aluminum alloy

ZL101 composition is simple, easy to melt casting, good airtightness, welding and cutting performance, but general mechanical properties. Suitable for casting thin-walled, large area, complex shape, strength requirements are not high parts, such as pump shell, gear box, instrument shell. Mainly sand and metal casting.

ZL101A in ZL101 based on the addition of trace Ti, grain refinement, strengthen the organization, the comprehensive performance of ZL101, ZL102, good corrosion resistance, can be used for general load engineering structures and motorcycles, automobiles, home appliances, instrumentation products, structural parts of high-quality castings. Its dosage is second only to ZL102, mostly used in sand and metal casting.

ZL102 good mobility, other properties and ZL101 similar, airtightness is better, can cast complex shape, thin-walled, strength requirements are not high die castings and thin-walled, large area, complex shape metal or sand castings. It is the most used casting aluminum alloy in civil products, no matter die casting or metal type, sand casting.

ZL104 worker crystal amount, plus Mn offset Fe harmful effect, casting performance, airtightness, corrosion resistance, good welding and cutting performance, but poor heat resistance, suitable for the system shape complex, large size, large load power structure parts, such as supercharger shell, cylinder head, cylinder liner, etc., the main die-casting, but also more sand and metal type casting.

ZL105, ZL105A plus Cu down Si, casting and welding performance is not as good as ZL104, room temperature and high temperature strength, cutting performance is better than ZL104, plasticity is slightly lower, poor corrosion resistance. Suitable for complex shape, large size, large load power structure parts, such as supercharger shell, cylinder head, cylinder liner, etc. ZL105A drop ZL105 impurity element Fe content, high strength, mechanical properties are better, more casting quality castings.

ZL106 improve Si content, add trace Ti, Mn, casting performance, high-temperature performance over ZL105, airtightness, corrosion resistance, can be used as a general load structure and the requirements of airtight, high-temperature work of the parts, mainly with sand and metal casting.

ZL107 casting airtight performance, good mechanical properties, welding and cutting performance in general, corrosion resistance is slightly worse, suitable for the production of general dynamic load or static load structure and airtightness requirements of parts, more sand casting.

ZL108 contains high Si, plus Mg, Cu, Mn, casting performance is excellent, coefficient of thermal expansion is small, good wear resistance, high strength, good heat resistance, but slightly lower corrosion resistance. Suitable for the production of internal combustion engine pistons and wear-resistant, size and volume stable parts, mainly with die-casting and metal casting, can also be used for sand casting.

ZL109 is a complex alloying Al-Si-Cu-Mg-Ni alloy, the Si content increased, plus Ni, casting performance, airtightness, high-temperature strength, abrasion resistance, corrosion resistance, the coefficient of linear expansion and density is reduced, suitable for the production of internal-combustion engine pistons and abrasion-resistant, dimensional volume stability of the parts, mainly with the metal-type casting and sand casting.

ZL111 is a complex alloy alloy, plus Mn, Ti, casting performance, corrosion resistance, airtightness, strength, welding and cutting performance in general. Suitable for casting complex shape, bear heavy load power structure parts, such as aircraft engine structure, water pump, oil pump, impeller, etc., the requirements of good air tightness, high temperature work parts. Mainly with metal type and sand casting, can also be used for die casting.

ZL114A should be ZL112, ZL112 is a complex alloying alloy, plus Mn, Ti, casting performance, corrosion resistance, airtightness, strength, welding and cutting performance in general. Suitable for casting complex shape, bear a significant load of power structure, such as aircraft engine structure, water pumps, oil pumps, impellers, etc., the requirements of good airtight, high-temperature parts. Mainly with metal type and sand casting, can also be used for die casting.

ZL115 casting performance is good, high mechanical properties, used for large load engineering structural parts, etc., such as valve shells, impellers, etc., mainly with sand and metal casting.

ZL116 to ZL115 alloy Zn, Sb, plus Ti, Be, grain refinement, Fe harmful effects of abatement, casting performance, airtightness, good mechanical properties, suitable for casting to bear a large load of power structure parts, such as aircraft missile parts, civilian products, comprehensive performance parts, mainly with sand and metal casting.

ZL117 is a complex alloying Al-Cu-Mg over eutectic wear-resistant alloy, containing Si amount of 19-22%, plus trace Mn and rare earth elements RE, into a soft matrix distribution of high-hardness primary crystalline Si mass points of advanced wear-resistant materials, casting performance, room temperature and high temperature strength, low coefficient of thermal expansion is good for casting of internal combustion engine piston, brake pads and wear-resistant, size and volume stability, high-strength Structural parts, mainly with metal casting, can also be used for sand casting. Ministry of aviation industry also developed three kinds of aluminum silicon alloy ZL112Y, ZL113Y, ZL117Y. ZL112Y and ZL113Y is Al-Si-Cu die-casting alloy, casting performance, airtightness, mechanical properties, suitable for casting of high strength, high working temperature, airtightness, good parts, but also can be used for pistons and other wear-resistant, size and volume stability, heat transfer performance parts, mainly with die-casting. Can also be used for sand and metal casting. With ZL108 alloy than, reduce Si content, improve Cu content, room temperature and high temperature performance is better than ZL108.

ZL201 room temperature and high temperature mechanical properties, general plasticity, general welding and cutting performance, poor mobility, tendency to thermal cracking, poor corrosion resistance, suitable for casting 200-300 ℃ work of structural parts, room temperature large dynamic load or static load parts, -70 ℃ work of the parts, more sand casting.

ZL201A impurities Fe, Si content is low, room temperature and high temperature mechanical properties over ZL201, cutting and processing welding performance is good, casting performance is poor, used for 300 ℃ work parts or room temperature large static and dynamic load parts, more sand casting.

ZL202 casting performance is good, high temperature strength, hardness, wear resistance, poor corrosion resistance, suitable for casting 250 ℃ load is not big parts, such as cylinder head, etc., mainly with sand casting and metal casting.

ZL203 reduced Si content, poor mobility, hot cracking tendency, poor corrosion resistance, but high-temperature strength, welding and cutting performance is good, suitable for casting below 250 ℃ load is not big parts and room temperature load parts, such as instrumentation parts, crankshaft case, etc., more sand casting andLow-pressure casting.

ZL204A is a high-purity, high-strength casting Al-Cu alloy, good plasticity, welding and cutting performance, casting performance is poor, suitable for casting large load structure, such as bearing seat, arm, etc., more sand casting and low-pressure casting.

ZL205A is the world's highest strength aluminum alloy, plasticity and corrosion resistance, cutting and processing welding performance, casting performance is poor, suitable for casting large load structure and air tightness requirements are not high parts, the main sand casting, low-pressure casting, can also be used for metal casting.

ZL207 High-temperature strength, casting performance in general, welding and cutting performance in general, room temperature strength is not high, suitable for casting 400 ℃ under the work of the structural parts, such as aircraft engine valve shell, oil refining industry heat-resistant components, etc., more sand casting and low-pressure casting.

ZL209 Tensile strength, yield point, high-temperature strength over ZL201A, welding and cutting performance is good, casting performance elongation is poor, suitable for casting higher temperature wear-resistant components, such as internal combustion engine parts, etc., more sand casting.

ZL301 Is the strongest corrosion resistance aluminum alloy, cutting and processing welding performance, high strength, good anodic oxidation performance, but the casting process is complex, castings are easy to loose, thermal cracking. Suitable for casting 150 ℃ under seawater and other corrosive media large load parts, such as marine ship components, oil industry pump shells, etc., more sand casting.

ZL303 High-temperature strength over ZL301, corrosion resistance is slightly worse, cutting and welding performance is excellent, casting performance is good, can not be heat treatment, low mechanical properties. Suitable for casting seawater, chemical, gas corrosive medium medium load aviation engines, missiles, internal combustion engines and other parts, mainly with pressure casting and sand casting.

ZL305 Add Zn drop Mg, casting performance, natural aging after the organization stability over ZL301, ZL303, loose thermal cracking tendency is small, add Ti, Be, comprehensive performance is good, anti-stress corrosion resistance, but high temperature mechanical properties are poor. Suitable for casting seawater, chemical, gas corrosive media below 100 ℃ work aviation machine, internal combustion engine parts.

ZL401 Casting performance is good, small tendency of shrinkage and thermal cracking, high mechanical properties, good welding and cutting performance, but the specific gravity, low plasticity, poor corrosion resistance. Commonly used in die casting, molds, templates and 200 ℃, medium load aviation machine, internal combustion engine, vehicle structure. Mainly using pressure casting, but also with sand and metal casting.

Physical Properties of Aluminum Alloys for Casting

| Alloy Code | Density ρ /g-cm-3 | Melting Temperature Range /°C | Average coefficient of linear expansion α /μm-(m-K) at 20~100℃.-1 | Specific heat capacity at 100 °C с /J-(kg-K)-1 | Thermal conductivity λ /W-(m-K) at 25°C-1 | Conductivity κ at 20°C (%IACS) | Resistivity ρ /nΩ-m at 20°C |

| ZL101 | 2.66 | 577-620 | 23.0 | 879 | 151 | 36 | 45.7 |

| ZL101A | 2.68 | 557-613 | 21.4 | 963 | 150 | 36 | 44.2 |

| ZL102 | 2.65 | 577 to 600 | 21.1 | 837 | 155 | 40 | 54.8 |

| ZL104 | 2.65 | 569-601 | 21.7 | 753 | 147 | 37 | 46.8 |

| ZL105 | 2.68 | 570-627 | 23.0 | 837 | 159 | 36 | 46.2 |

| ZL106 | 2.73 | - | 21.4 | 963 | 100.5 | - | - |

| ZL108 | 2.68 | - | - | - | 117.2 | - | - |

| ZL109 | 2.68 | - | 19 | 963 | 117.2 | 29 | 59.4 |

| ZL111 | 2.69 | - | 18.9 | - | - | - | - |

| ZL201 | 2.78 | 547.5 to 650 | 19.5 | 837 | 113 | - | 59.5 |

| ZL201A | 2.83 | 547.5 to 650 | 22.6 | 833 | 105 | - | 52.2 |

| ZL202 | 2.91 | - | 22.0 | 963 | 134 | 34 | 52.2 |

| ZL203 | 2.80 | - | 23.0 | 837 | 154 | 35 | 43.3 |

| ZL204A | 2.81 | 544-650 | 22.03 | - | - | - | - |

| ZL205A | 2.82 | 544-633 | 21.9 | 888 | 113 | - | - |

| ZL206 | 2.90 | 542-631 | 20.6 | - | 155 | - | 64.5 |

| ZL207 | 2.83 | 603-637 | 23.6 | - | 96.3 | - | 53 |

| ZL208 | 2.77 | 545 to 642 | 22.5 | - | 155 | - | 46.5 |

| ZL301 | 2.55 | - | 24.5 | 1047 | 92.1 | 21 | 91.2 |

| ZL303 | 2.60 | 550-650 | 20.0 | 962 | 125 | 29 | 64.3 |

| ZL401 | 2.95 | 545-575 | 24.0 | 879 | - | - | - |

| ZL402 | 2.81 | - | 24.7 | 963 | 138.2 | 35 | - |