Difference between low pressure casting and gravity casting

Date: 2024-08-05 Categories: Blog Views: 8884

Both low pressure casting and gravity casting arealuminumA type of casting process, low-pressure casting is also known as reverse casting.Gravitational casting(math.) genusLow-pressure castingIt is the most important of all. The difference between it and gravity casting is mainly in this aspect.

Difference in the principle of casting operation:

Difference in the principle of casting operation:

Low pressure castingAlso known as anti-gravity low-pressure casting is the name of its casting method is through the gas pressure against gravity casting molding, as shown in the figure on the right: through the sealing of the crucible into the gas (usually 0.06 ~ 0.15MPa)), the aluminum liquid in the role of pressure through the middle of the pipeline, the product for the molding of the casting, pressure for a certain period of time, the aluminum water cooled in the mold cavity molding, through the discharge of the gas pressure, open the mold The mold is opened by discharging the air pressure and the product is taken out.

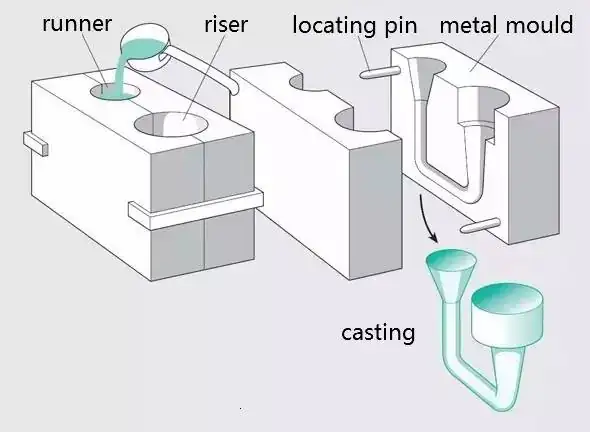

gravitational castingRefers to the aluminum water through the action of gravity casting → filling → solidification contraction → castings, this process is called gravity casting, gravity casting is a relatively long development of aluminum alloy casting process, more molds are divided into different non-metallic type gravity casting (refers to not allow metal molds usually refers to the turn)sand castingmanufacturing), metal-type recasting (meaning the use of metal molds)

Difference in Pressure Levels

Low pressure castingThere is a 0.06~0.15MPa by air pressure for mold filling and casting.

gravitational castingIt is only by gravity that the mold is filled, not relying on external pressure, but on the weight of the metal liquid itself for flow and filling.

The difference between casting accuracy and quality

Low pressure castingDue to the external pressure, the flow speed of the metal liquid can be better controlled under pressure, the product is fuller and the surface quality is higher. Aluminum water crystallizes under pressure, the casting has a higher density and a smoother surface.

gravitational castingSince it can only flow naturally, the ability to control the flow of the liquid metal is weak, and the surface is poorer than that of low-pressure casting, and it is usually only possible to make thick-walled products.

Differences in application scenarios:

Low pressure casting is commonly used in demanding high-end automotive, aerospace and other industries because of its high precision and quality control. Gravity casting is often used to produce relatively thick products because of its low cost and simple process.