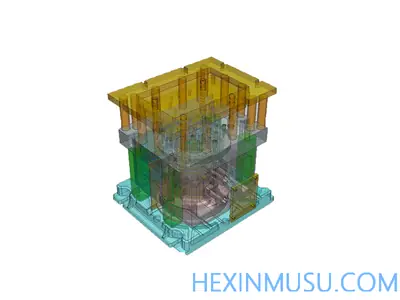

Composition and design of aluminum die casting mold

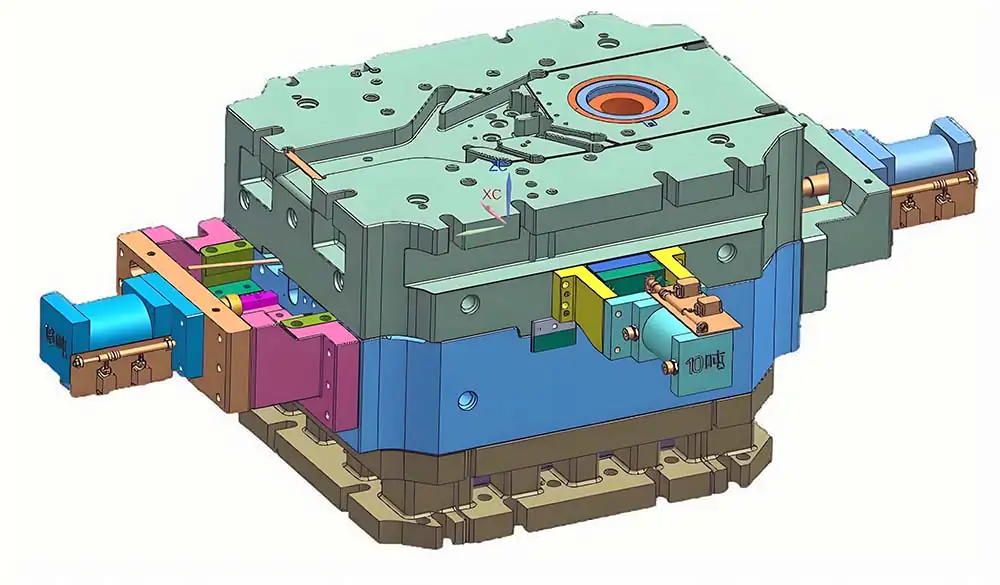

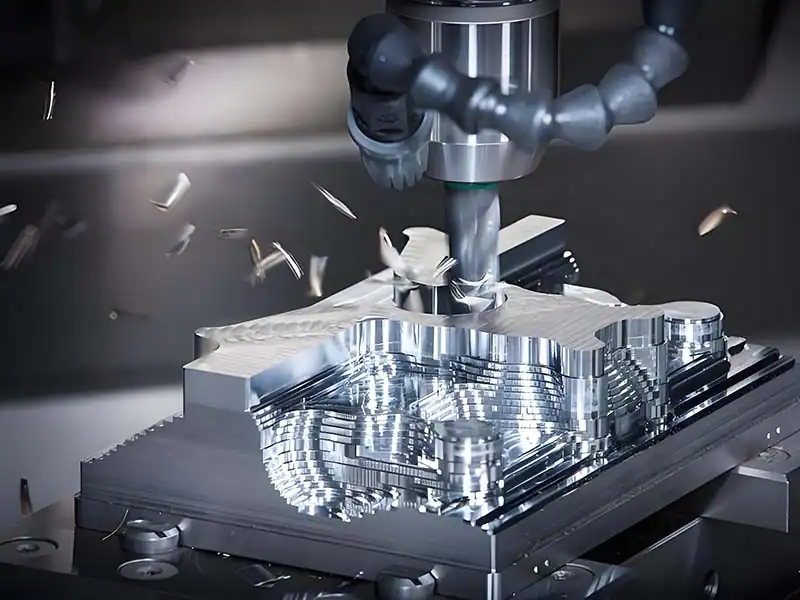

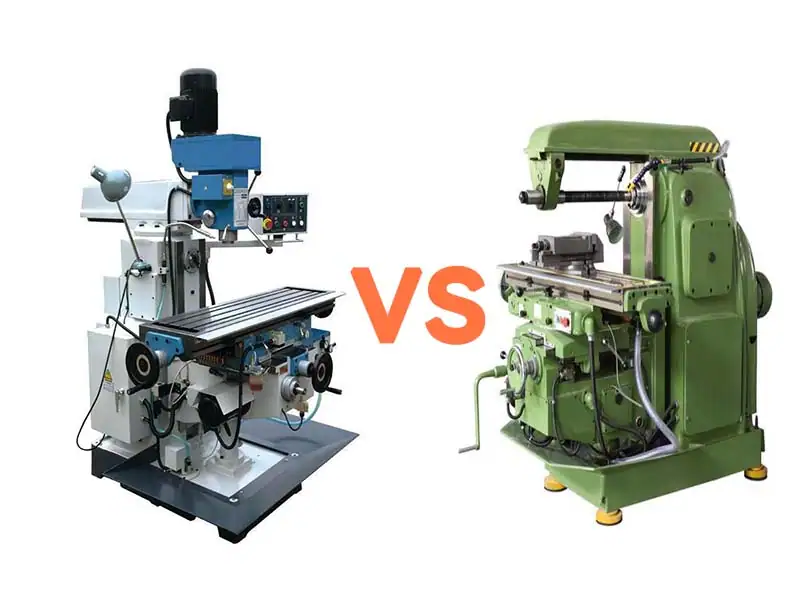

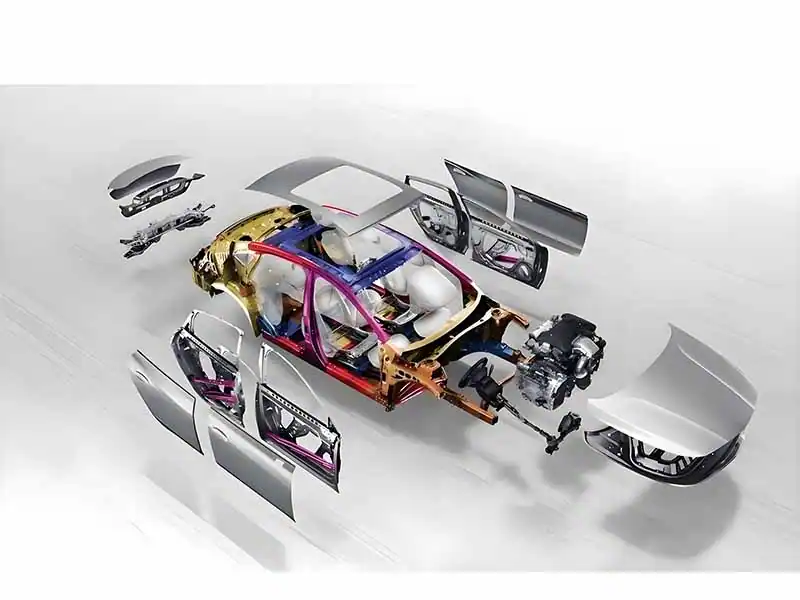

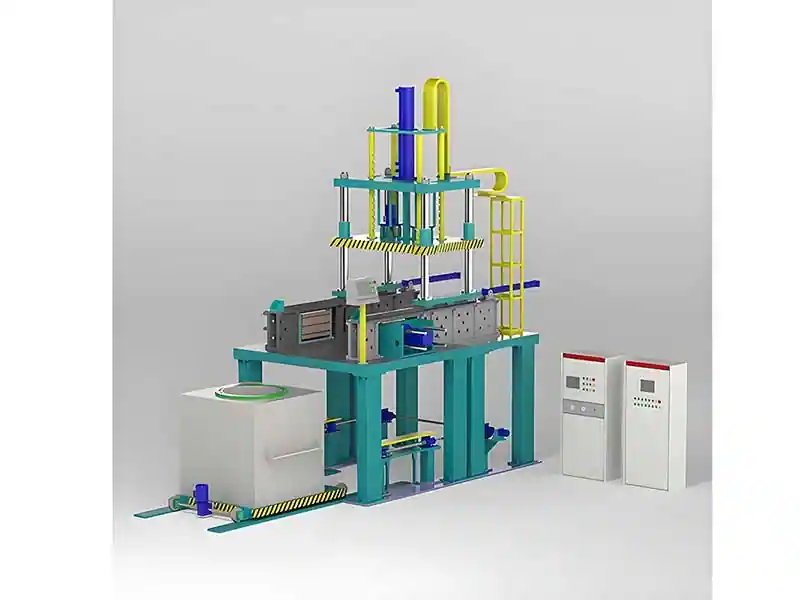

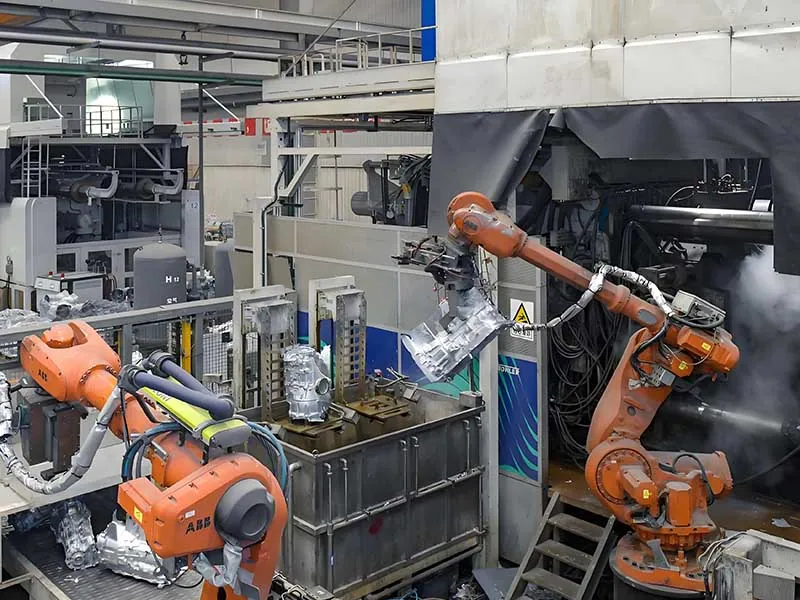

Aluminum die casting is a highly efficient manufacturing process commonly used for mass production of precision aluminum alloy castings. Compared with traditional casting methods, aluminum die casting molds can achieve higher production efficiency and finer casting dimensions. Aluminum die casting mold design and composition directly affects the quality of castings, production cycle and mold life, therefore, the design of a high-performance aluminum die casting mold is critical. Aluminum die casting die refers to the tool used to manufacture aluminum alloy high pressure castings, usually consists of die kernel, die seat, die core, cooling device, sliding device, ejector device and other components. The following is a detailed analysis of aluminum die casting die: the main components of aluminum die casting die aluminum die casting die design key considerations aluminum die casting die classification aluminum die casting die and die casting machine can be divided into: Horizontal cold chamber die casting...