ADC12 Die-Cast Aluminum Alloy Comprehensive Guide: Compositional Properties, Mechanical Properties and Industry Applications

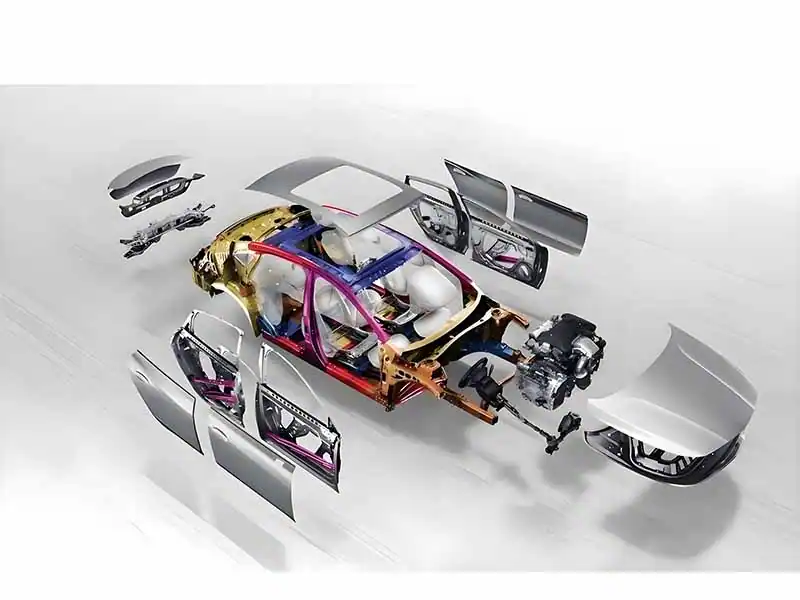

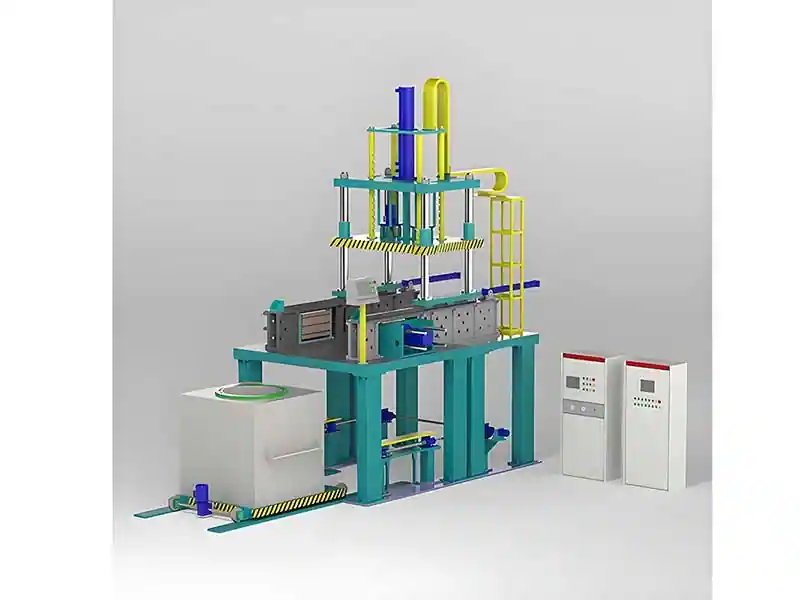

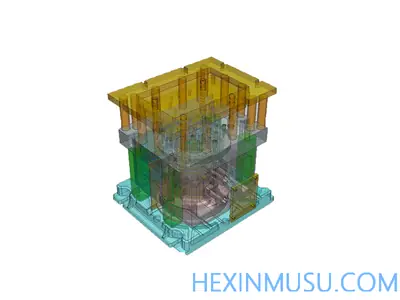

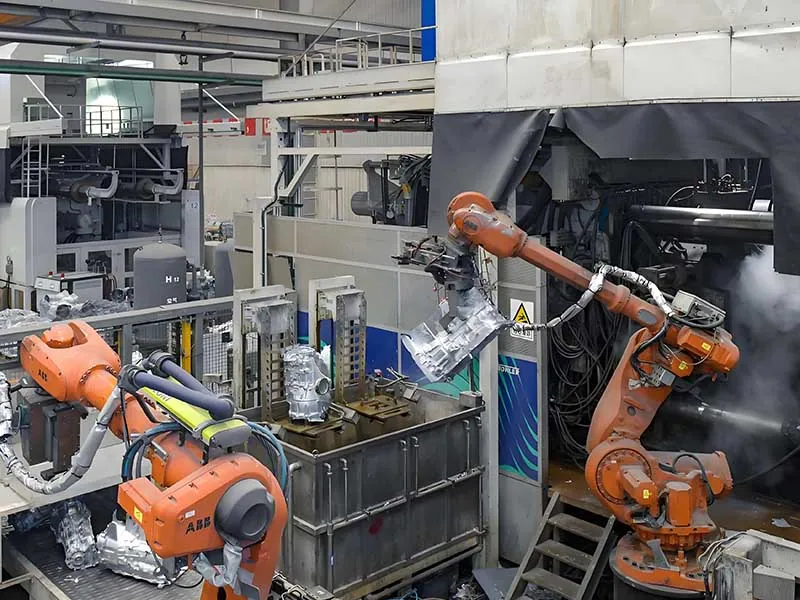

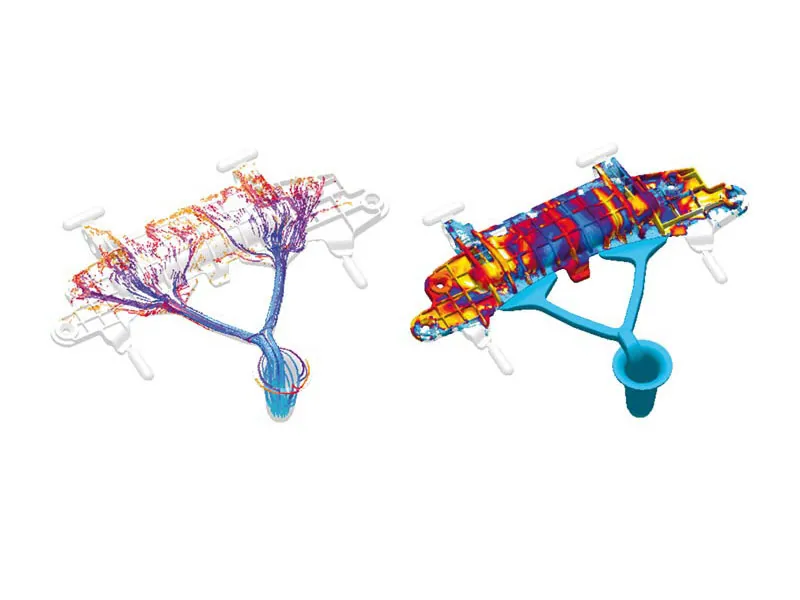

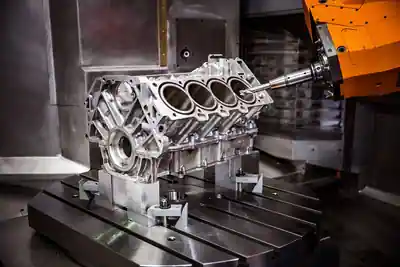

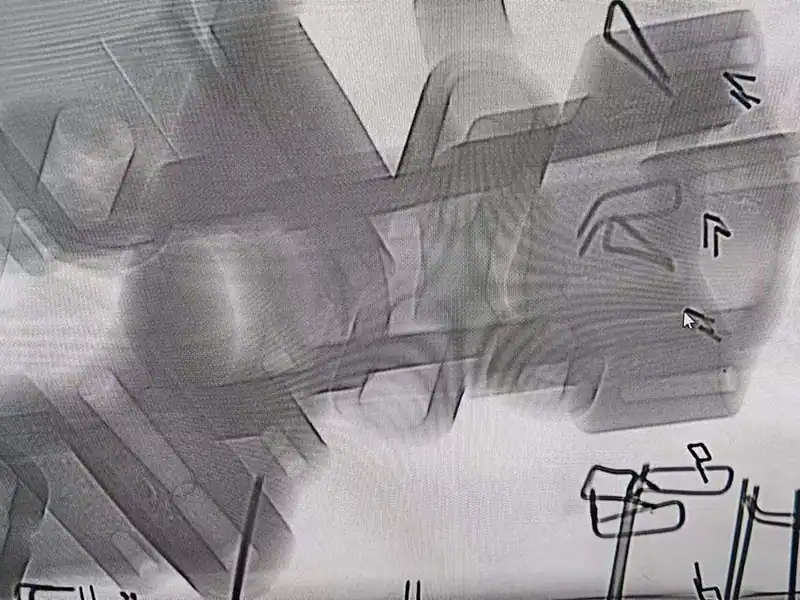

ADC12 (Japan JIS standard 12 aluminum) is a high-performance Al-Si-Cu die-cast aluminum alloy, which implements the JIS H 5302-2000 standard. The alloy is known for its excellent casting fluidity, good machinability and high dimensional stability, and is particularly suitable for the production of complex thin-walled components. Its typical composition (Si 9.6-12.0%, Cu 1.5-3.5%) ensures that the material combines good strength, heat and corrosion resistance while keeping production costs low. In the automotive industry, ADC12 is widely used in the manufacture of key components, including cylinder head covers, various types of sensor housings, engine mounts, transmission components and motor housings and other structural parts. It is one of the most common materials used in the die casting industry. Material Composition JIS Standard CuSiMgZnFeMnNiSnAl ADC121.5-3.59...