Quality of castings

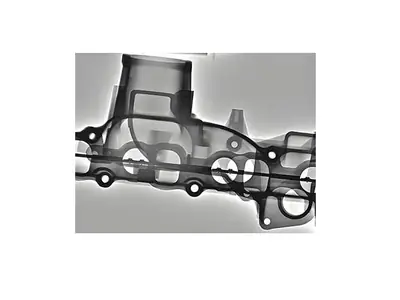

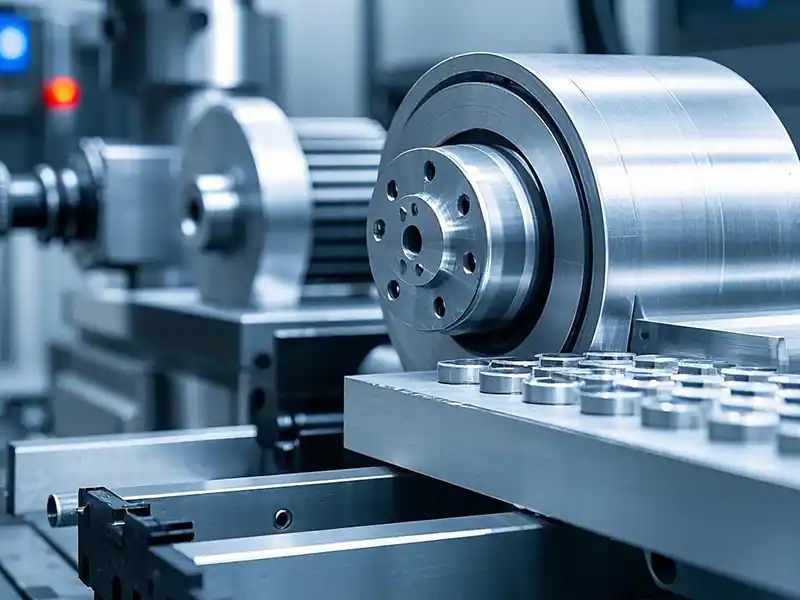

The reliability of aluminum castings lies in the strict casting quality verification process. Through a set of casting inspection methods, quality management. Not only to ensure that each casting meets the design standards, but also to enhance its performance and long-term stability. Aluminum casting inspection methods Hexin adopts a series of precise aluminum casting inspection methods, each casting can meet the quality requirements. Each aluminum casting is rigorously inspected to meet predetermined standards for performance, dimensions and chemical composition. 1. Radiography and Visual Inspection Quality control of castings uses visual inspection techniques to ensure that castings are free of defects such as cracks, porosity, voids, etc. Each casting is inspected in detail to ensure that there is no distortion or bending. Once the inspection is complete, the casting is compared to the quality control program and process requirements. Finally, all inspection results are...