Sand casting mold material selection

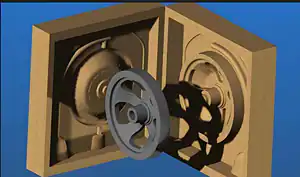

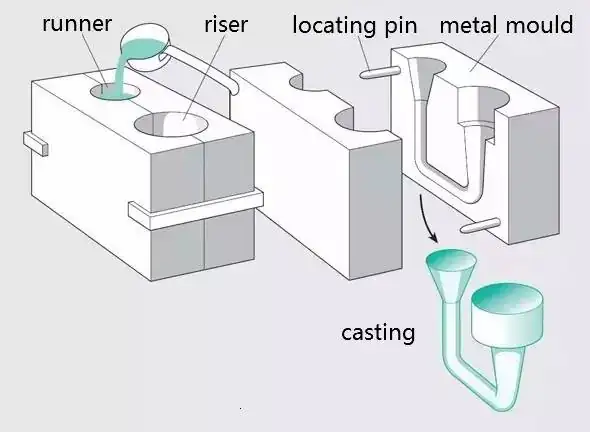

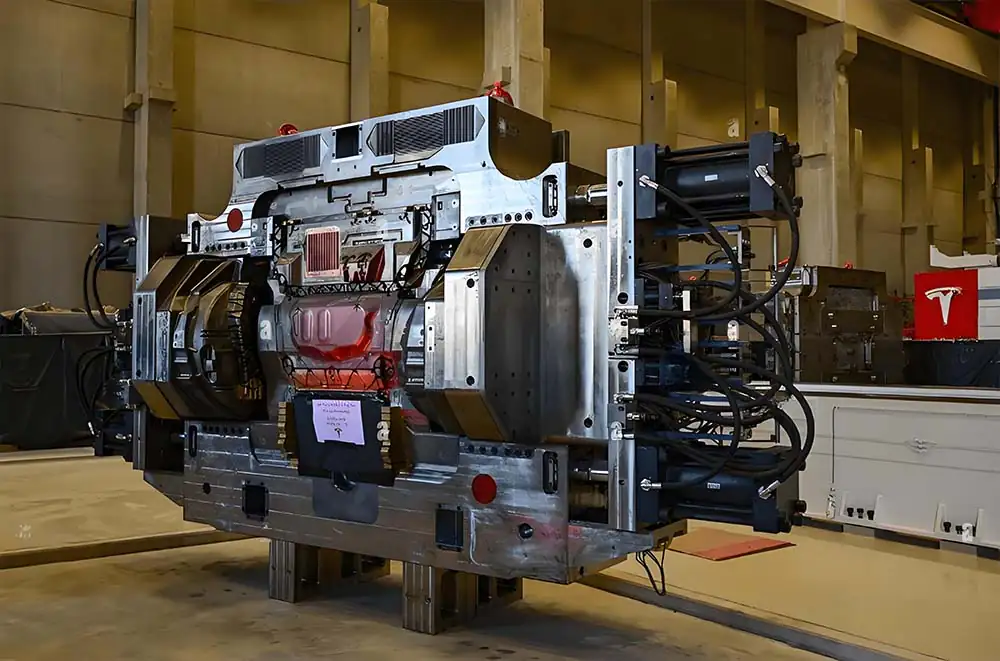

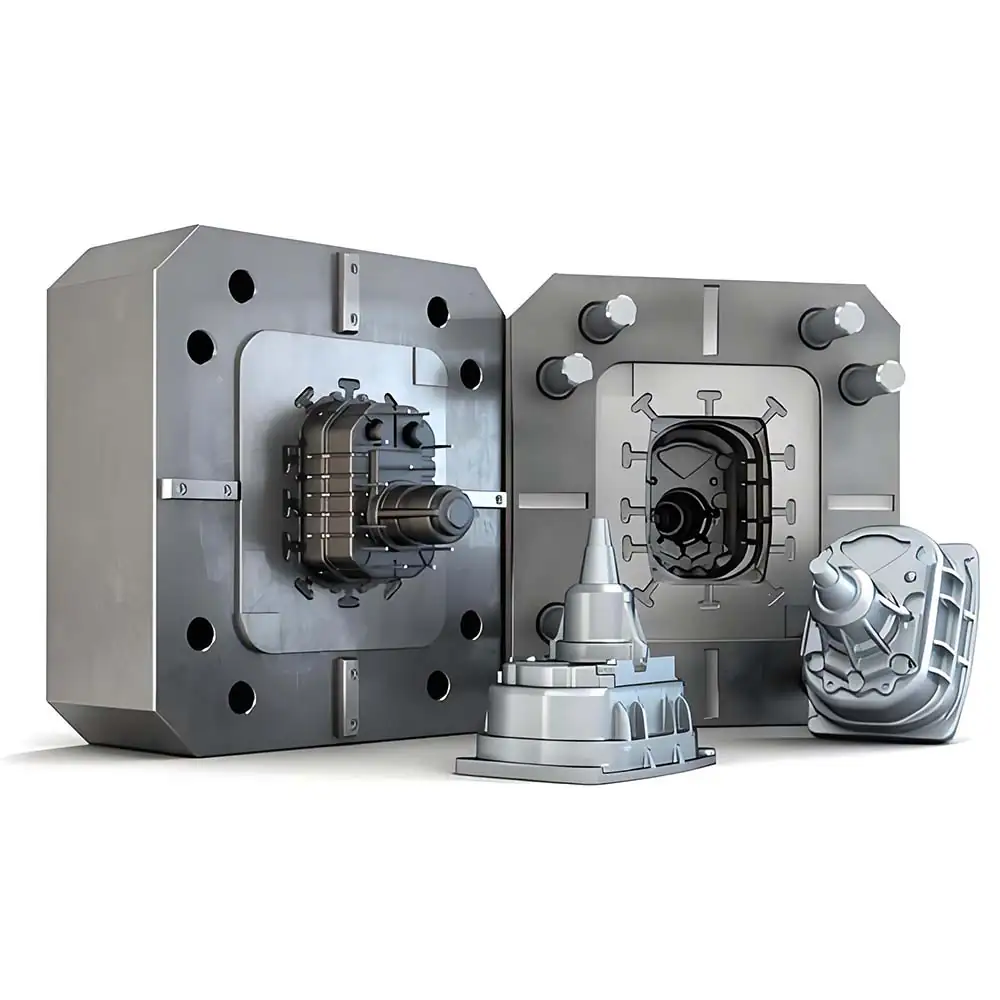

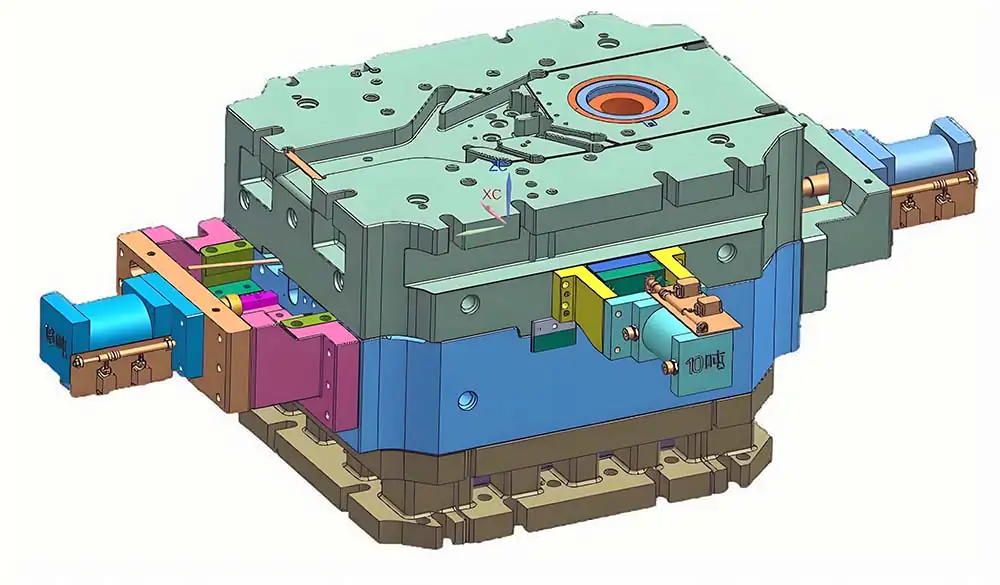

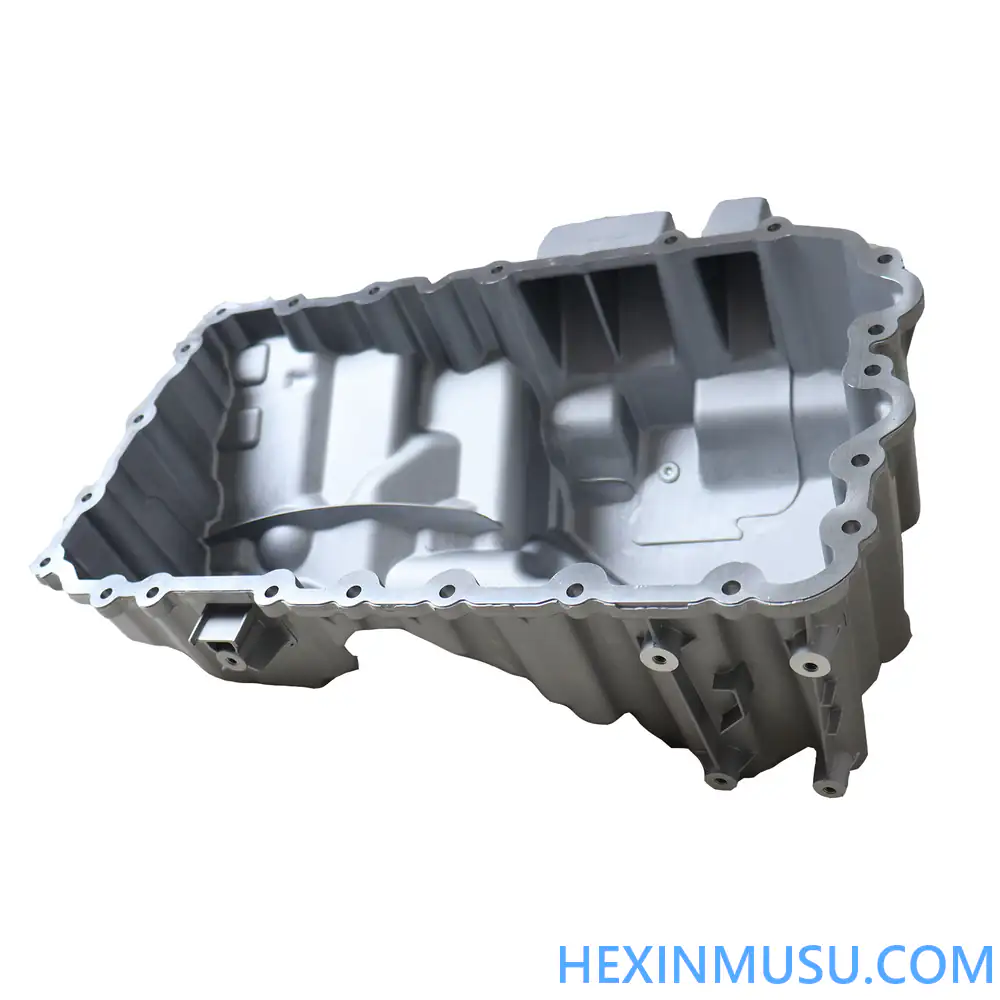

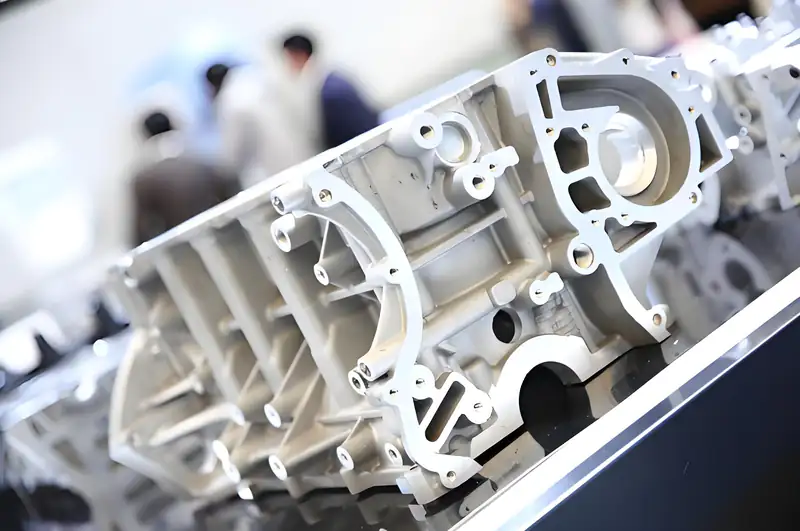

What materials are used for casting molds? Casting molds use the following materials: casting molds for the number of uses due to the casting production varies, mainly divided into metal molds and non-metallic molds non-metallic mold materials are: wood, plastic, etc.. Metal mold materials are: plastic, aluminum alloy, cast iron, steel and so on. Wooden molds At present, wooden molds are widely used in manual or small batch production, but with the increasingly stringent environmental requirements, the use of wood will be more and more limited, rather than true casting. True casting uses Styrofoam board as the material, cuts and bonds it into shape, and then pours it into a casting. Compared with wood molds, this method not only saves wood, but also makes castings with higher dimensional accuracy and better surface roughness. Plastic Molds The application of plastic molds is on the rise, especially with the introduction of processable plastics to the market...