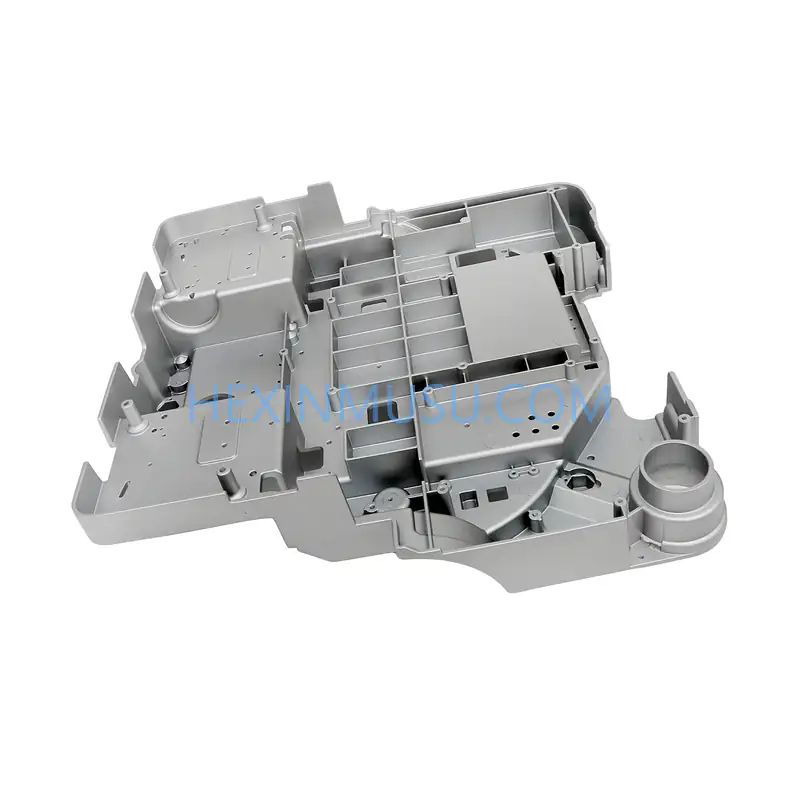

aluminumDie-casting motor radiator cover is a motor accessory manufactured by high-precision aluminum alloy die-casting process, dedicated to motor cooling system. Its main function is to provide an effective heat dissipation channel for the motor to ensure the normal operation of the motor under high load and to avoid performance degradation or damage due to overheating. Due to its excellent thermal conductivity and durability, aluminum alloy motor radiator covers are widely used in electric motors, home appliances, power tools and other high-performance electrical equipment.

| Product Name: | Aluminum Motor Heat Dissipation End Cap Accessories |

| Mounting Location. | Top of motor |

Product usage scenarios

Motor equipment fieldGenerators, starter motors, micro motors, environmental protection air-conditioning motors, water-cooled air-conditioning motors, air compressor motors, negative-pressure blowers, electric motors, electric tricycle motors, cooling tower motors, power tool motors, air-conditioning compressors, refrigerator compressors, non-explosion-proof motors, and geared motors.

Air cooler manufacturing:: Manufacture of air coolers

Industrial and commercial applications: Factory production lines, automated equipment, commercial air-conditioning systems and other occasions

Other special areas:: Research equipment, medical equipment, aerospace equipment

Main features:

- Excellent thermal performance: Aluminum alloy material has good thermal conductivity, which can effectively conduct the heat generated during the operation of the motor to the outside, thus keeping the motor running stably and preventing overheating.

- Lightweight design: The lightweight nature of the aluminum alloy results in a lighter weight radiator cap, which reduces the overall equipment weight and improves the overall efficiency of the motor system.

- High corrosion resistance: Aluminum alloy material has strong corrosion resistance, adapts to various environmental conditions, and is able to resist corrosive factors such as oxidation, moisture, and salt spray to extend service life.

- Precision casting process: High-precision aluminum alloy die-casting technology is used to ensure that each radiator cap is of the same size, with a beautiful shape and smooth surface, which helps to improve the overall heat dissipation efficiency.

- High strength and vibration resistance: Aluminum alloy die castings have high structural strength and vibration resistance while ensuring heat dissipation performance, and are able to withstand vibrations generated during the internal operation of the motor as well as the influence of the external environment.

- environmental: Aluminum alloy is a recyclable material that meets environmental requirements and has a low environmental impact.