Tension clamp (tension clamp, strain clamp, dead-end clamp), as an important fixture, is mainly used to fix the wire, so that it can withstand the tension of the wire, and will be properly hung to the tension string group or tower.

From the point of view of structure and installation conditions, tensioning clamps can be broadly classified into the following two categories:

Non-Conductive Removable Tension Clamps

This type of tension-resistant clamp is required to withstand the full tensile force of the conductor or lightning conductor. The clamp holding force is required to be not less than 90% of the rated tensile strength of the installed conductor or lightning conductor and does not function as a conductor of electricity. A significant advantage is that this type of wire clip can be removed after completion of the wire installation for separate use in other applications. Common types of clamps of this type include bolt-type tensioning clamps and wedge-type tensioning clamps. Bolt-type tensioning clamps are usually connected by strong bolts to ensure that the wire is firmly fixed, its installation and removal is relatively easy, suitable for a variety of different installation environments. Wedge-type tensioning clamps utilize the principle of wedge structure to fix the wire tightly in them, which has good stability and reliability.

Conductive non-removable tension clamps

This type of tension-resistant wire clip, in addition to withstanding the full tensile force of the conductor or lightning conductor, but also at the same time as a conductor of electricity to play a role. Because of this, this type of wire clip once the installation is completed, it can not be disassembled, so it is also figuratively known as "dead wire clip". Because of its electrically conductive properties, the installation process must strictly comply with the provisions of the relevant installation procedures, and carefully carry out the operation to ensure the quality and safety of the installation. For example, before installation, you need to clean the contact surface of the wire and the wire clip to ensure good conductivity; the installation process to ensure that the wire clip is tightened with the right amount of force, neither too loose to cause poor contact, nor too tight to damage the wire or the wire clip.

Tension clamps in the erection and maintenance of power lines play a vital role, different types of tension clamps for different applications, the correct selection and use of tension clamps to ensure the stable operation of the power system is of great significance.

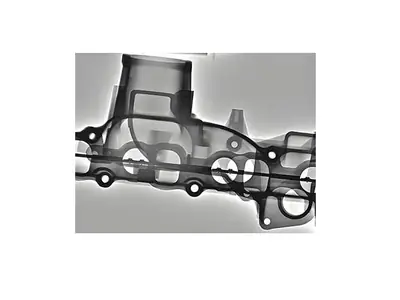

| branding | He Xin (1910-1984), Chinese actor | item number | NLL-2 |

| geometry | bolt pattern | characterization | Moisture Resistant, Insulated |

| Scope of Application | (electric) cable | operating frequency | (sth. or sb) else |

| model number | NLL-2 | range | tensioning clamp |

| material (that sth is made of) | aluminum | Product Use | power construction |

| Applicable wires | LGJ-50-95 | weights | 2.1kg |

Application Scenarios:

Tensioning wire clamps are used to fix the wire or lightning line in the non-linear tower tensioning insulator strings, the role of the anchor, also used to fix the tensioning tower tensioning wire clamps Advantages: 1. Effectively eliminate small animals or foreign objects lap caused by short-circuit accidents; 2. Prevent condensation flash branding, filth flash branding, icicles sticking to the snow caused by the electrical accidents; 3. Prevent corrosion of acid rain, salt spray and hazardous chemical gases on the inlet and outlet of transformer lines; 4. Avoid pedestrians accidentally touching the exposed electrical contacts and personal injury or death caused by accidents; 5. shield and measuring device fully enclosed operation can prevent lawbreakers from stealing electricity: 6. buckle structure, simple installation, can be reused

Ningbo Hexin Manufacturing Features.

- Specialized Manufacturing Capabilities

- Specialized in aluminum alloy manufacturingLtd. is a professional manufacturer of aluminum alloy for the mold factory development of aluminum alloy products manufacturing supplier, was established in 2010, Ningbo Hersin Co., Ltd. many years of aluminum alloy mold manufacturing, product production has accumulated a wealth of experience in aluminum alloy casting and technical strength.

- Diversified product productionLtd. not only produces a variety of aluminum alloy casting molds (die-casting molds, low-pressure casting molds, gravity casting molds) but also produces a variety of aluminum alloy products, a wide range of services, covering a variety of industries such as automotive industry, medical equipment, communications and electronics and so on. There is a perfect aluminum alloy supporting industries, stamping, plastic, rubber and other service experience.

- Specialization of services

- custom processingLtd. provides processing and customization services, which can design, process and assemble the shell according to the specific needs of customers to meet their individual needs.

- adaptableVertical management mode, flexible adaptability of various products, rapid production of various products processing.

- Stabilized quality.

- Excellent team: Ningbo Hersin has a group of engineers who focus on the design and production of aluminum alloy casting, and together they make up Ningbo Hersin, making the quality more stable and reliable.

- quality control: In the production process, the company focuses on quality control to ensure that each product meets the quality standards and is tested before leaving the factory to provide customers with a reliable product guarantee.

- Quality after-sales

- Professional TeamNingbo Hexin provides professional after-sales service team, which can respond to customer's needs and problems in time and provide technical support and solutions.

- Long-term cooperation: Ningbo Hexin pursues long-term and stable cooperation, obtains customers' full trust through high-quality products and excellent service, and has been widely praised.