Services

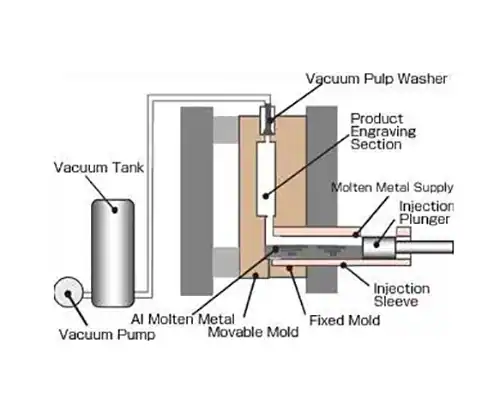

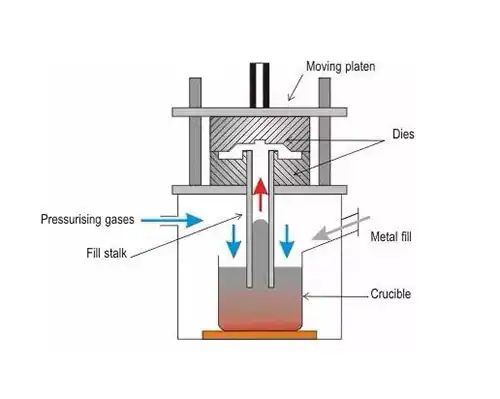

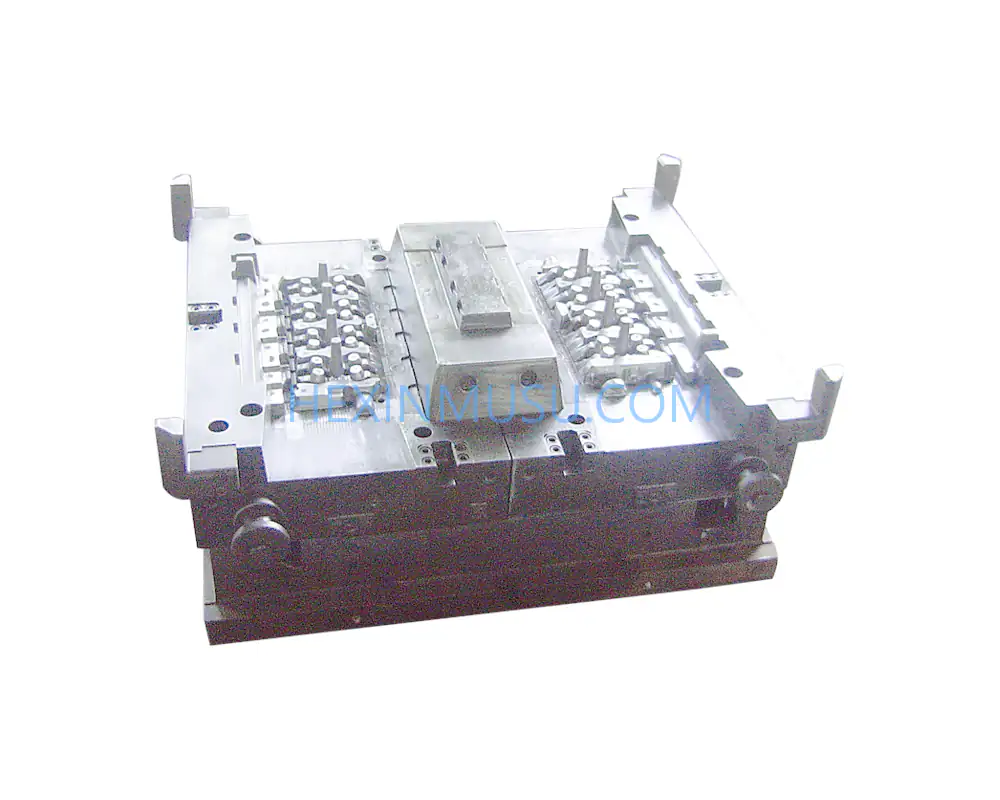

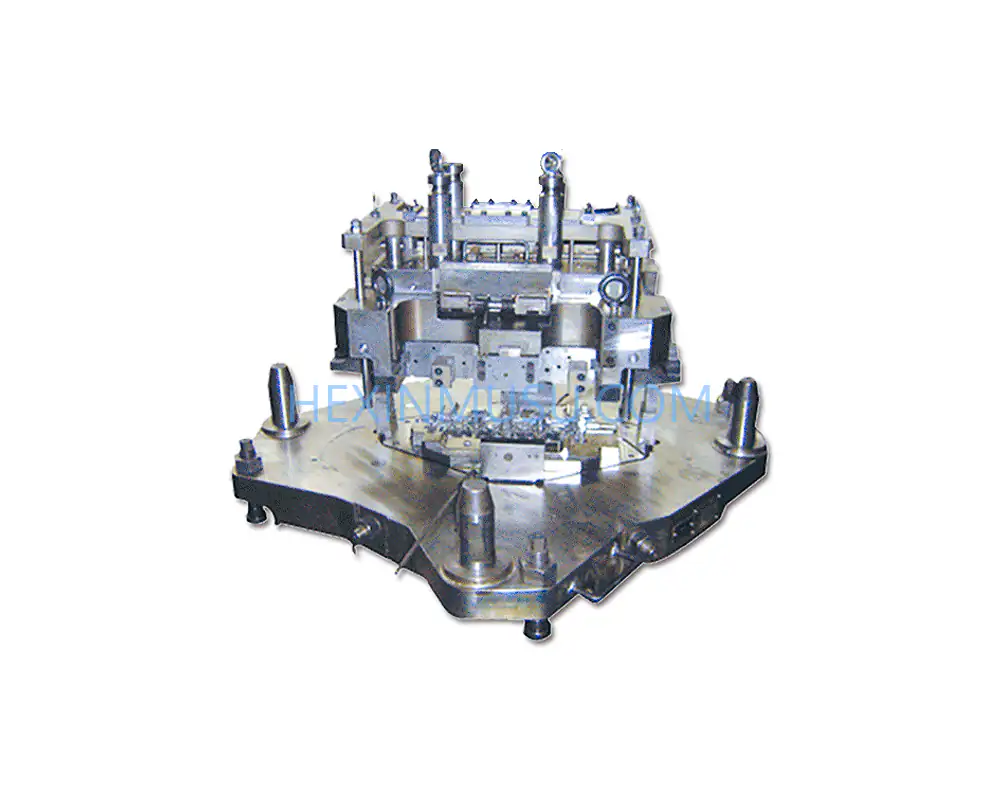

Through the aluminum alloy material properties, hardness requirements, gas density requirements, structural tightness, structural difficulties are examined. Low-pressure casting, gravity casting, pressure casting and other casting processes are analyzed to determine the production process of aluminum alloy parts. The number of aluminum alloy products open mold, dimensional accuracy level analysis to determine the mold heat-resistant steel type, steel characteristics for production.

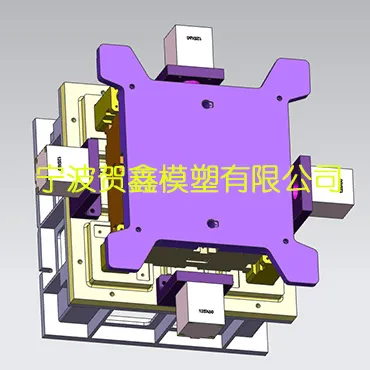

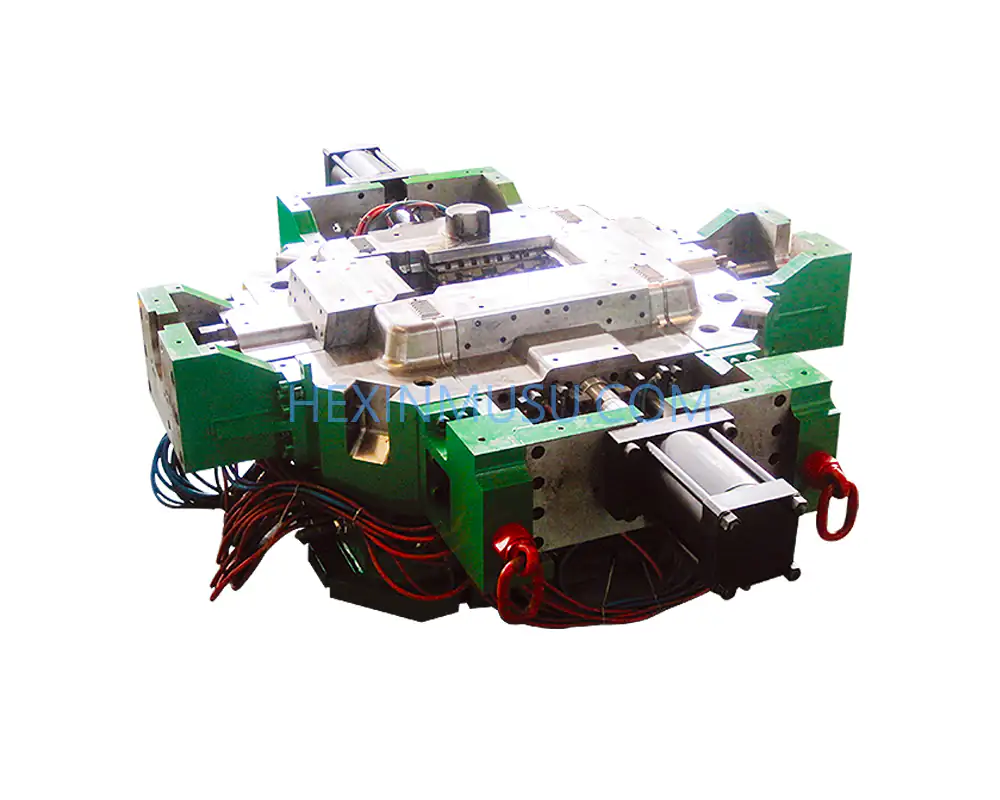

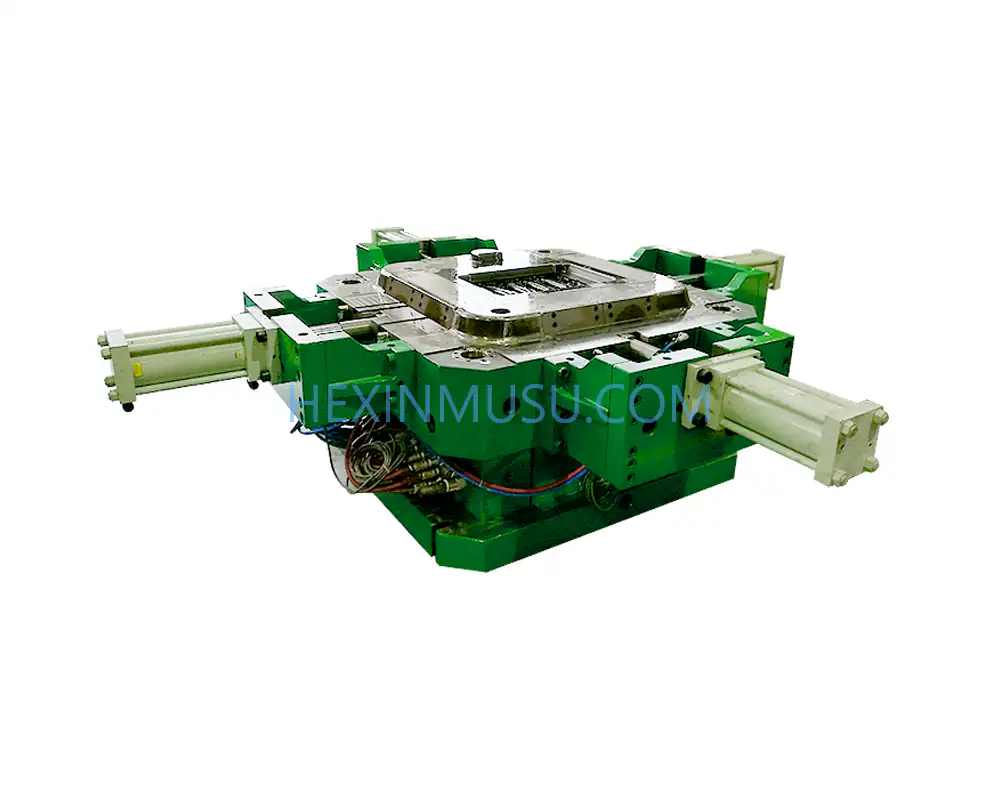

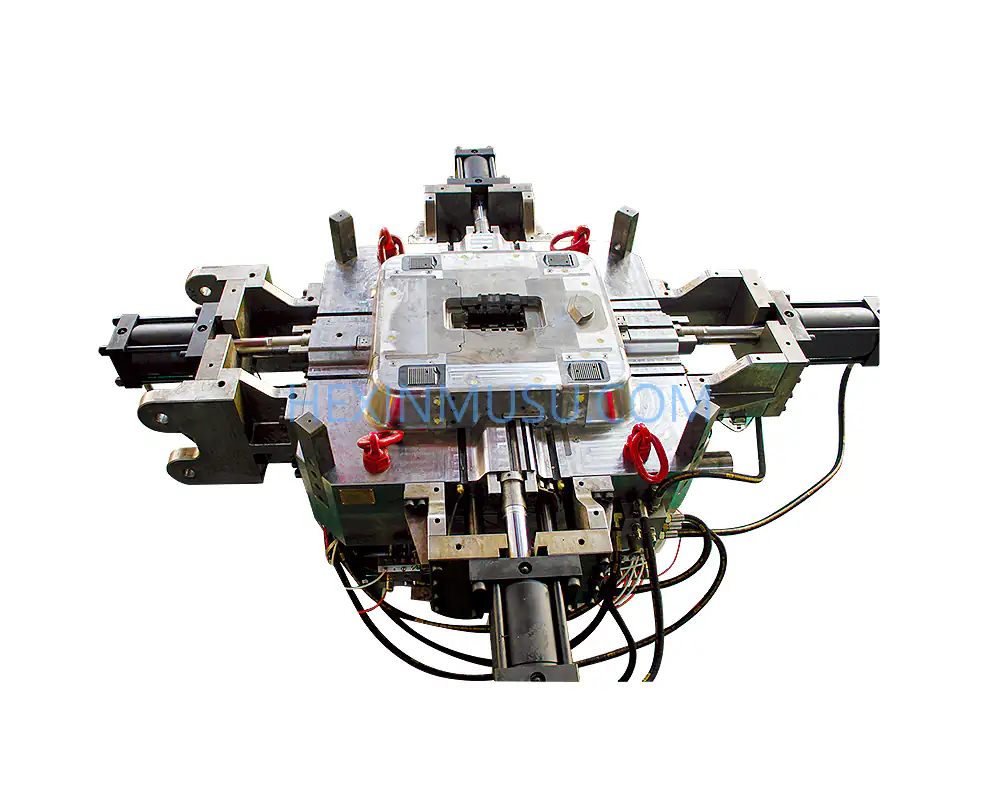

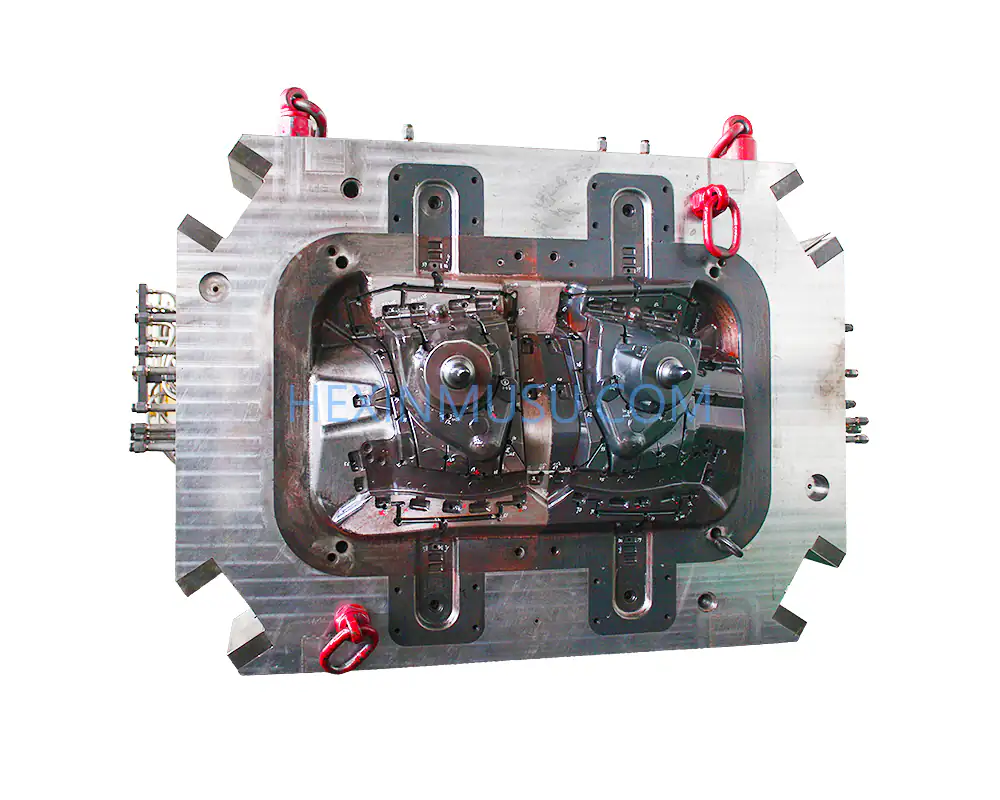

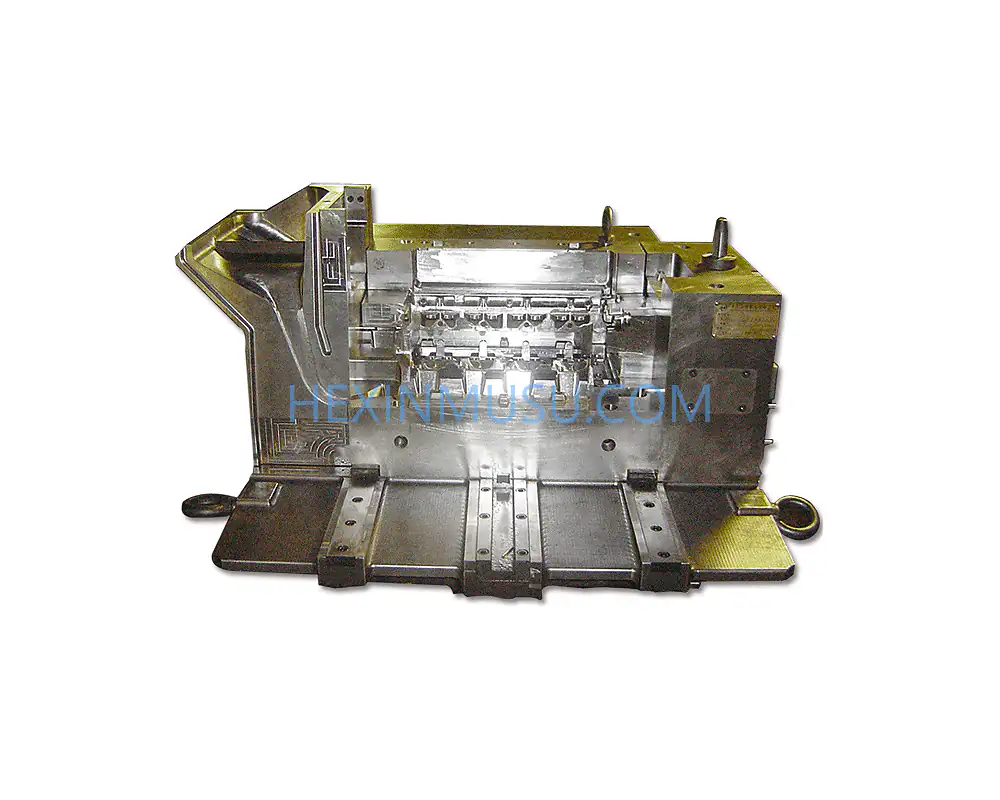

- High pressure die casting mold

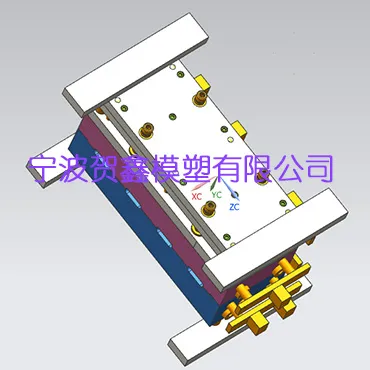

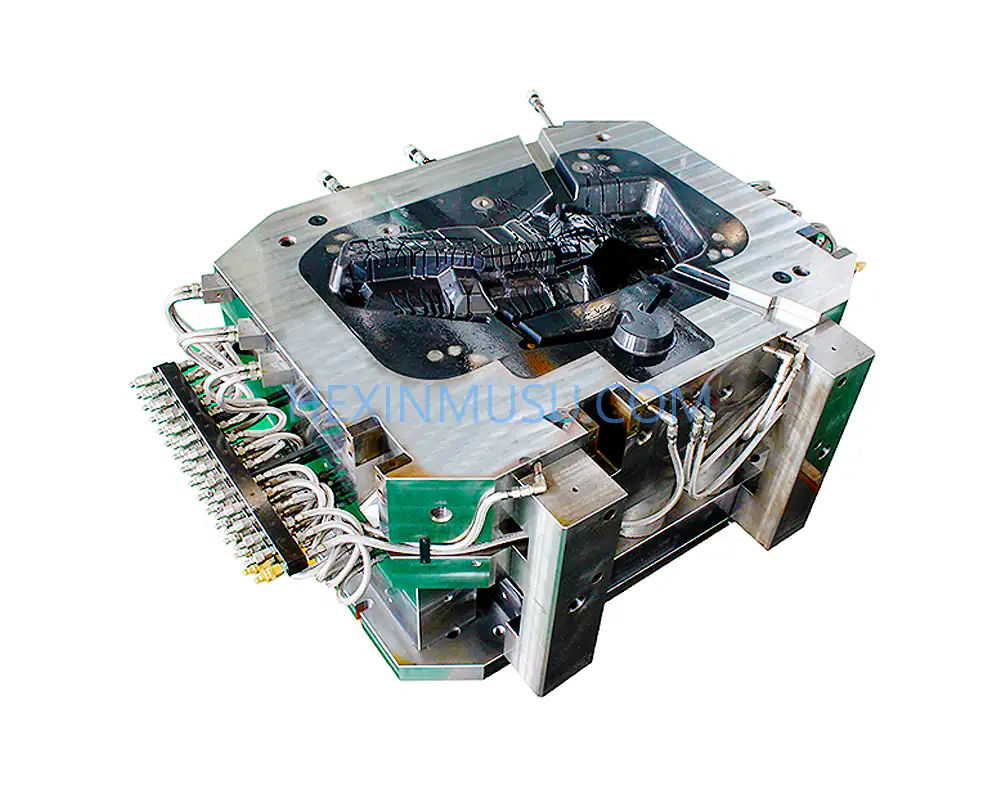

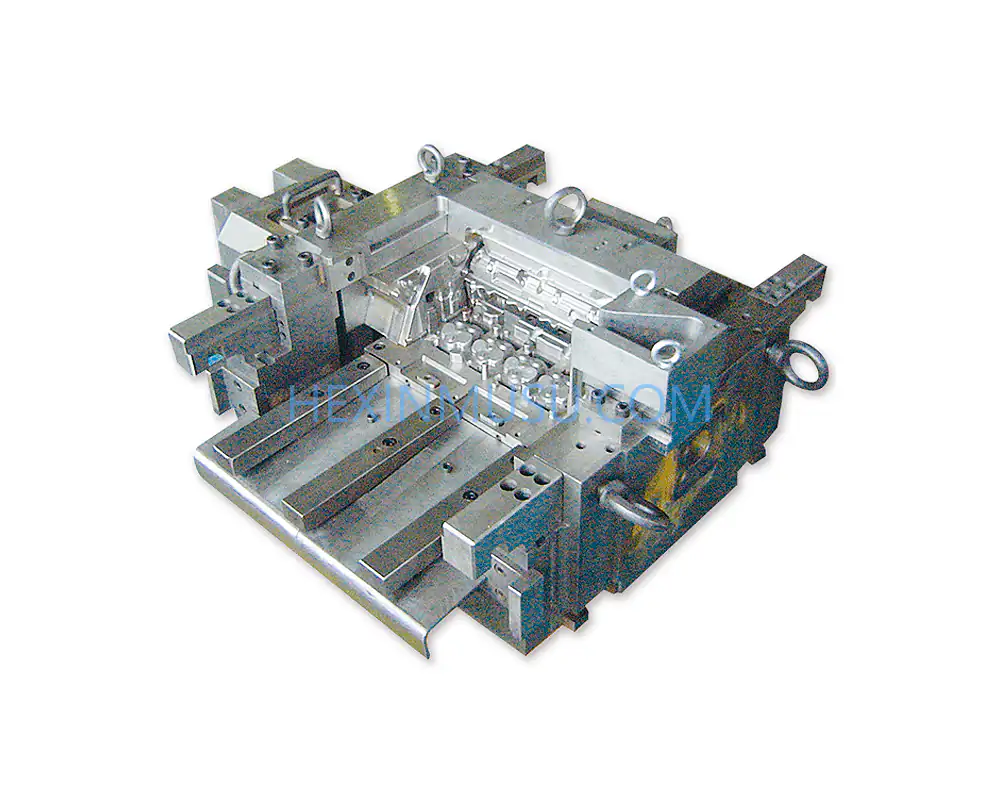

- Low pressure casting mold

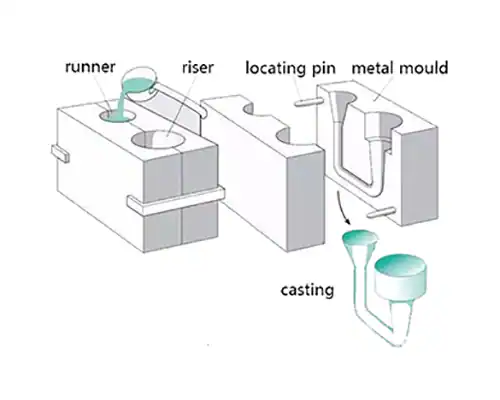

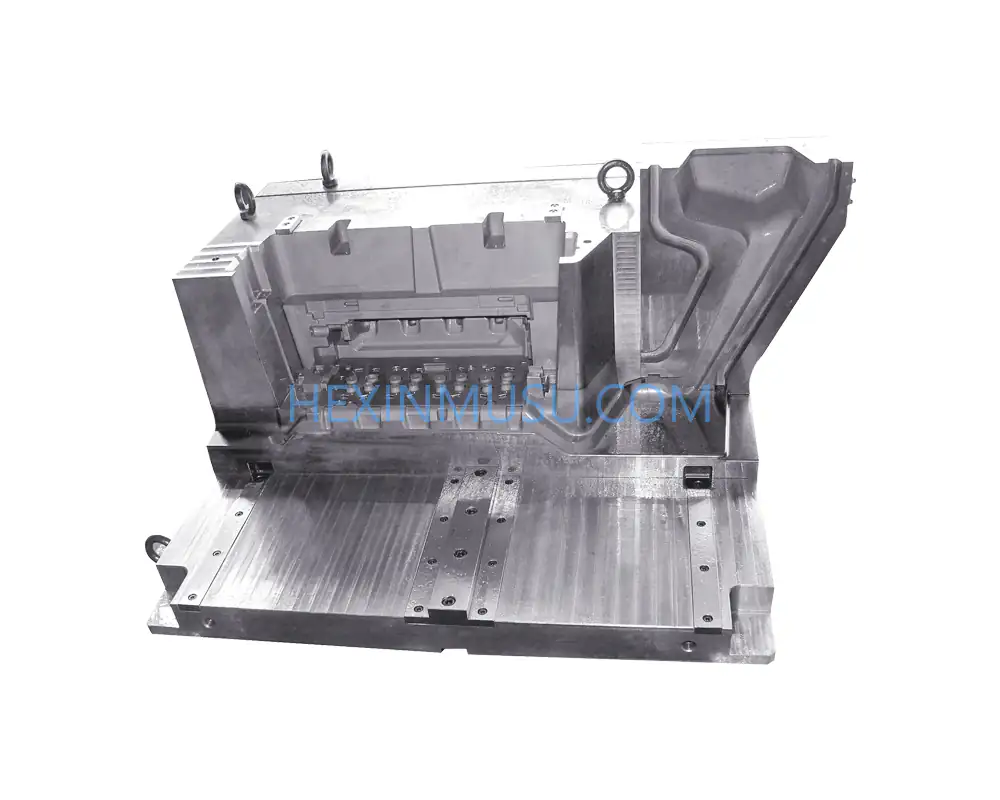

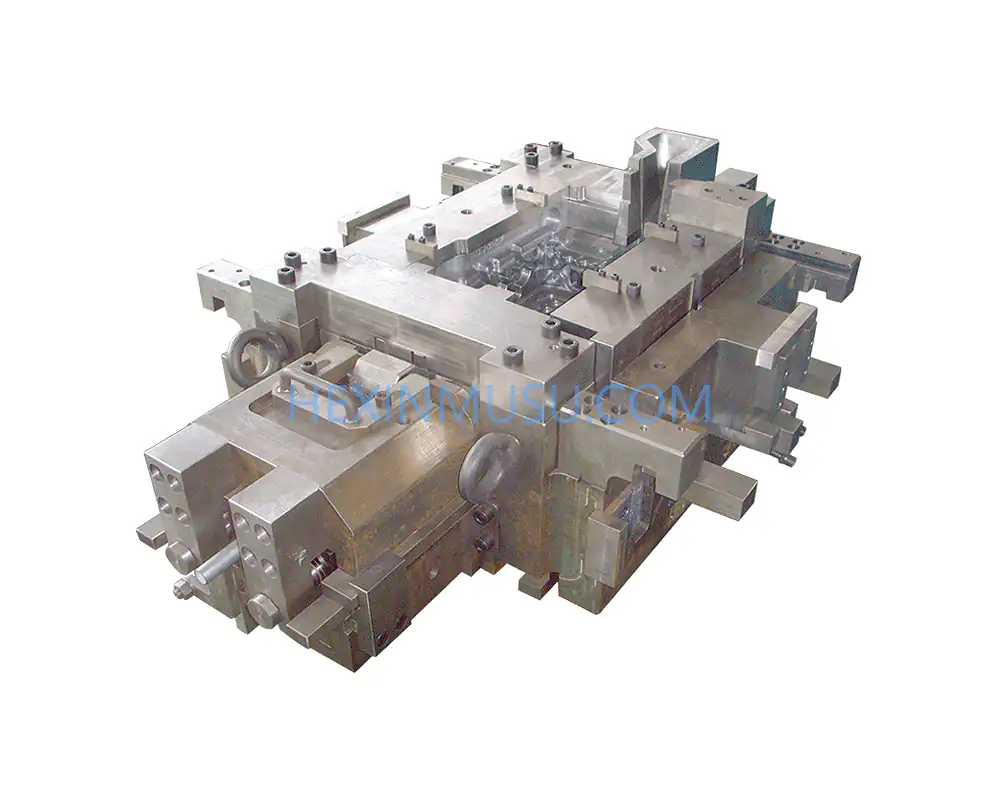

- Gravity casting mold

Our Advantages

Ningbo Hexin Mould & Plastic Co., Ltd. was formerly known as Ningbo Hexin Mould Factory - is a factory specializing in the manufacture of molds to provide customers with mold solutions, Ningbo Hexin Mould & Plastic Co., Ltd. is located in the famous Ningbo Beilun Port, adjacent to the Hangzhou-Ningbo Expressway and the same three high-speed, 28 kilometers away from the airport in Ningbo, sea, land and air transportation is extremely aspects. Ningbo Hexin factory was established in 2010 Ningbo Hexin Mould & Plastic Co., Ltd. has nearly 20 years of nearly 30 years of experience in mold manufacturing, die casting, low pressure, gravity has a strong professionalism, for other molds, such as: stamping, extrusion, Takagi, plastics, rubber, red punch, but also has a certain knowledge reserve, through the use of advanced CAD, CAF, CFD. design technology for scientific design. Then we carry out fluid analysis of the molds and optimize the structure of the products by combining the results of the fluid analysis with our practical experience, and then we carry out the development of the molds and the production of the products. We provide customers with one-stop solutions for aluminum alloy products and their supporting products.

Service Process

Mold Manufacturing

Customers place orders → mold manufacturing → steel procurement → machining center roughing → mold heat treatment → CNC finishing → EDM → wire cutting → assembly → mold fitting → test mold → mold inspection (unqualified modification reassembly inspection)

product production

Customer order → product production → raw material procurement → melting → degassing / deslagging → billet making → grinding → heat treatment → product shot blasting → appearance inspection → CNC machining → product testing (unqualified scrapping)→wrap→Finished goods in storage

Service

- gravity casting

- high-pressure casting

- low-pressure casting

Mold Manufacturing

die casting mold