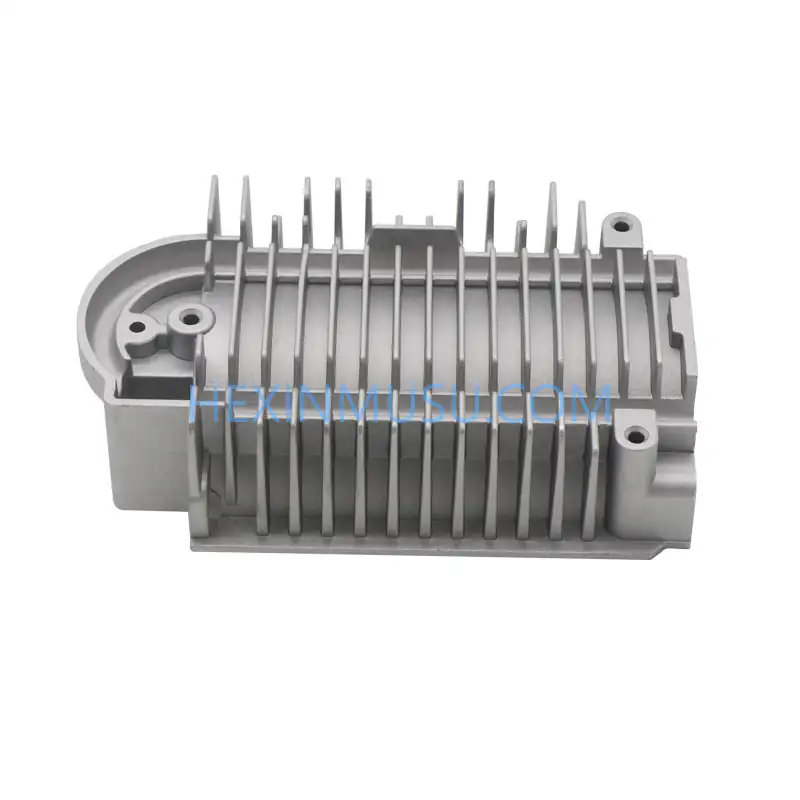

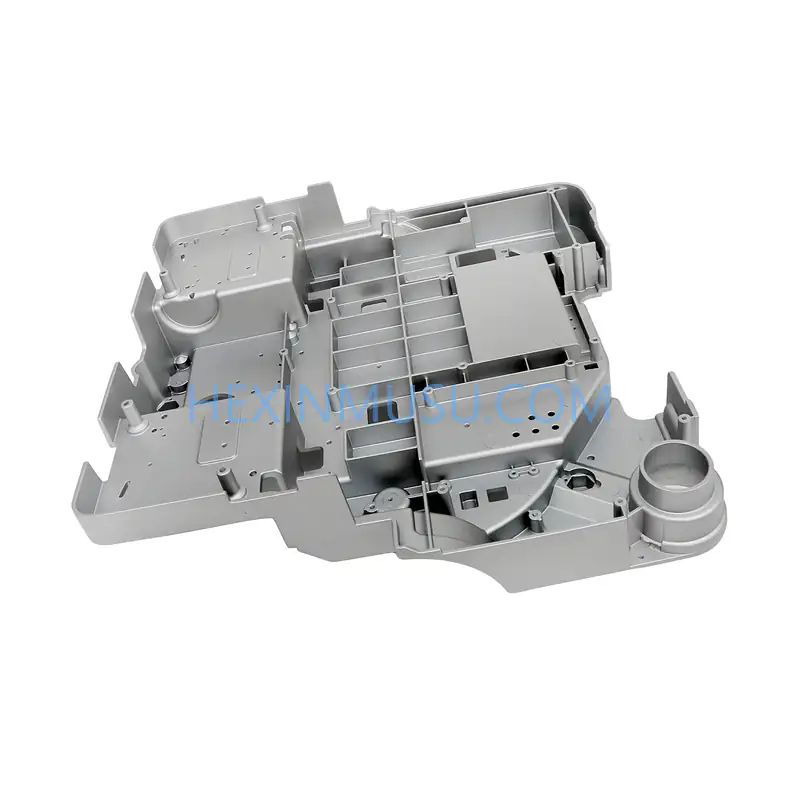

motor vehiclesaluminumThe engine water hose connector is a key accessory designed for automotive engine cooling systems, mainly used to connect the engine with the water hoses in the cooling system to ensure that the engine can be efficiently and safely maintained at the optimal operating temperature range. The connector is precision-designed to efficiently flow coolant between the engine, radiator and other related components to ensure engine cooling and prevent overheating.

| Product Name: | Automotive engine coolant hose connection housing |

| Mounting Location. | Automobile engine radiator |

Aluminum alloy as a material has light weight, high strength, excellent corrosion resistance, and good thermal conductivity, which makes aluminum alloy water pipe connectors still work stably in high temperature and high pressure environments and have a long service life. In addition, the advantages of aluminum alloy also include light weight, which reduces the overall burden on the vehicle, can improve fuel efficiency, and is suitable for modern automotive needs for lightweight design.

Application Scenarios:

Automotive Cooling System: Used to connect the engine, water pump, radiator and other components to ensure smooth coolant flow and keep the engine temperature stable.

Commercial vehicles and heavy trucksEngine cooling systems in large commercial vehicles and heavy-duty trucks that are subjected to high load conditions.

High Performance Vehicles: Used in high-performance sports or racing cars, it keeps the cooling system running efficiently under extreme driving conditions.

electric vehicle: With the development of electric vehicles, aluminum alloy water pipe connectors are also widely used in battery cooling systems to ensure stable battery pack temperatures.

Product Advantage:

- Durable: Aluminum alloy plumbing connectors have a long service life, are resistant to high temperatures and corrosion, and are able to adapt to extreme temperature and pressure changes in automotive engine systems.

- Enhanced cooling effect: Through optimized thermal conductivity design, it helps the coolant absorb and dissipate heat efficiently, reducing the risk of engine overheating and improving vehicle performance.

- weight reduction: Aluminum alloys are lighter than traditional metal connectors, contributing to overall vehicle weight reduction, fuel economy and dynamic performance.

- High strength and sealing: Aluminum connectors are able to withstand the impact of high-pressure coolant flow and, together with high-precision machining and sealing gaskets, ensure the efficient operation of the cooling system.